-

Home

-

Products

-

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

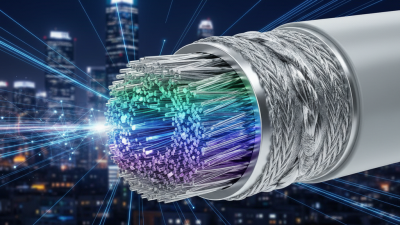

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

In the fast-evolving field of optical cables, "Glass Yarn For Optical Cables" plays a pivotal role. Dr. Emily Carter, a leading expert in fiber optics, emphasizes, "The right glass yarn can significantly enhance performance." With advancements on the horizon, understanding these materials becomes crucial for stakeholders.

Glass yarn, known for its lightweight and strength, contributes to the durability of optical cables. The demand for high-speed internet accelerates innovation in this sector. However, challenges remain. One must consider variations in quality and the manufacturing processes involved. Not all glass yarn meets the required standards.

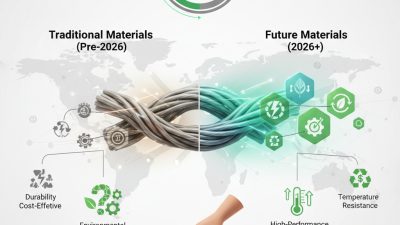

As we approach 2026, staying informed is vital. Experts in the industry highlight the importance of material selection and its impact on overall cable efficacy. This knowledge allows businesses to make informed decisions. Achieving optimal results requires diligence. The innovations in glass yarn have a promising future, yet they also force us to reconsider existing practices and quality controls.

Glass yarn plays a crucial role in the optical cable industry. It serves as a protective layer for fiber optics. Many manufacturers use glass yarn for its lightweight and durable properties. The unique structure of glass yarn not only ensures flexibility but also enhances performance in harsh environments. It withstands temperature fluctuations and resist chemicals, which is vital for outdoor applications.

However, the production of glass yarn is not without challenges. Quality control remains a significant concern. Variations in thickness can lead to inconsistencies in performance. Manufacturers often struggle with achieving the desired tensile strength. This inconsistency can affect the long-term viability of optical cables. It’s essential to address these issues to ensure reliability and functionality.

Moreover, the environmental impact of glass yarn production is a topic of discussion. While it is recyclable, the process still consumes resources. The industry must find sustainable methods to produce glass yarn. Balancing efficiency and eco-friendliness is a challenge. Continuous improvements in production techniques are needed to make glass yarn a fully sustainable option.

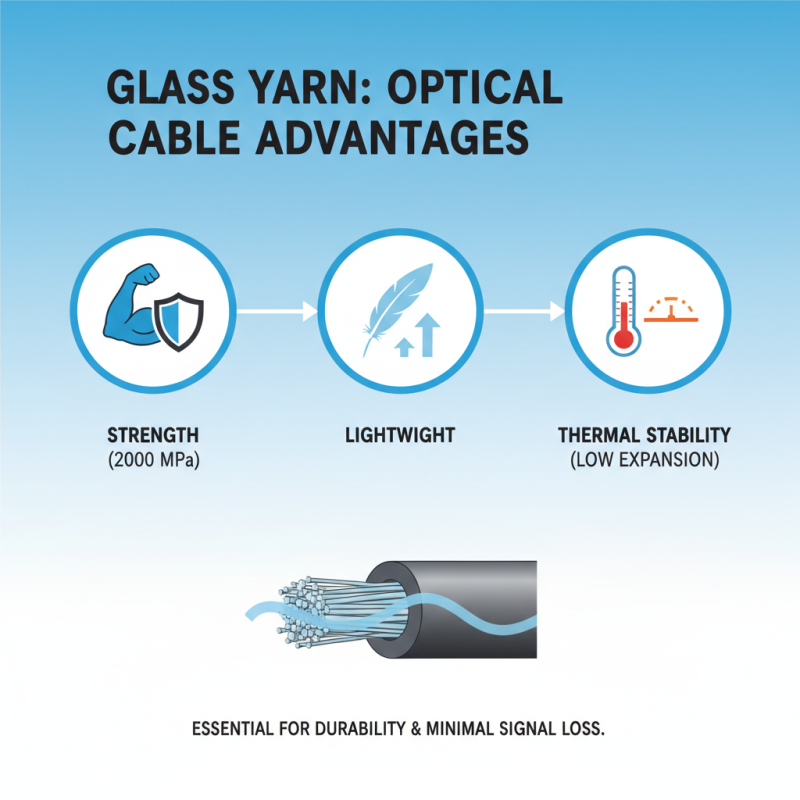

Glass yarn has emerged as a crucial material in the production of optical cables. This is due to its strength, lightweight nature, and thermal stability. It boasts a tensile strength of around 2000 MPa, which is essential for cable durability. Additionally, its low coefficient of thermal expansion ensures minimal signal loss, a key factor in optical performance.

To optimize performance, consider the glass yarn’s chemical resistance. It can withstand harsh environments without degrading. This is vital for cables installed in diverse conditions, ranging from urban to industrial settings. Interestingly, data from the Optical Fiber Communications Conference indicates that glass yarn reduces attenuation by up to 0.2 dB/km.

Tips: Use high-quality yarn to ensure long-term reliability. Test yarn samples in real-world conditions. It helps in identifying weaknesses. Remember, even small flaws can impact performance significantly. Prioritize sourcing materials that meet industry standards. That will enhance the overall effectiveness of your optical cables.

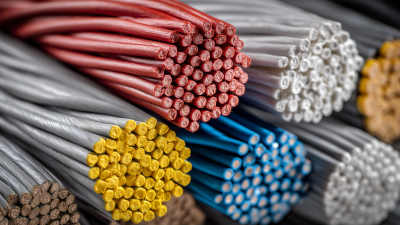

Glass yarn plays a crucial role in the production of optical cables. It provides excellent protection and insulation. Its lightweight nature is a significant advantage, making installation easier, especially in complex environments. The durability of glass yarn is noteworthy; it resists harsh weather conditions and ensures long-term performance.

When woven into cables, glass yarn enhances strength. This reinforcement can prevent damage during handling and installation. Additionally, glass yarn is non-conductive, reducing the risk of electrical interference. Many engineers appreciate how it supports signal integrity. However, some may overlook potential challenges. Working with glass yarn can be more difficult compared to synthetic materials. Careful handling is essential to avoid breakage during manufacturing.

Applications for glass yarn in optical cables are diverse. They range from telecommunications to data centers. The demand for faster and more reliable connections drives innovation. Yet, there are questions about cost-effectiveness. Some projects may find traditional materials more budget-friendly. Balancing performance and expense is vital for many applications. Choosing the right material is a step that requires careful thought.

The evolution of glass yarn technology is set to redefine the landscape of optical cables. Recent studies indicate that the demand for high-performance optical cables has surged by 15% annually. This uptick is driven by the accelerating growth of internet services and increasing data transmission needs. The incorporation of glass yarn in these cables offers significant advantages. Glass yarn provides enhanced tensile strength and thermal resistance, which are crucial for performance in challenging environments.

Innovations in glass yarn technology present new opportunities. Emerging techniques, such as advanced weaving and coating methods, allow for lighter and more flexible yarns. These advancements make cables easier to install. Reports suggest that the integration of nanotechnology could lead to glass yarn with improved dielectric properties. However, industry experts note that transitioning to these innovations poses challenges. There is a need for comprehensive testing and standardization to ensure reliability. The shift toward sustainable production methods must also be addressed, as environmental concerns grow.

As companies navigate these complexities, there’s potential for groundbreaking solutions. The focus on durability and functionality could reshape our connectivity future. While the progress is promising, critical reflections on manufacturing practices remain necessary. Consistent evaluation of performance metrics will ensure that the advancements in glass yarn are both effective and responsible.

This chart illustrates the projected growth of glass yarn usage in optical cables across different applications from 2023 to 2026. The data is based on industry trends and expected innovations in glass yarn technology.

When selecting the right glass yarn for optical cables, several key factors come into play. The diameter of the yarn is crucial. A thinner yarn can provide better flexibility but may compromise strength. Reports suggest that yarns with a diameter of 0.1 mm to 0.2 mm are often preferred for their balance of strength and flexibility. However, these specifics can vary based on application needs.

Material composition is essential. High silica content typically enhances thermal and chemical resistance. Studies indicate that glass yarn with over 90% silica can significantly improve performance. Yet, some applications may benefit from alternative compositions, which might not perform at the same level. Users often overlook durability when choosing materials, aiming only for immediate performance.

**Tip:** Always assess the manufacturing process, as it directly impacts yarn quality. Check for certifications to ensure standards are met.

**Tip:** Remember that cost can reflect quality. A lower price may mean compromises in material or production, leading to potential failures.

In some cases, industry professionals report challenges in gaining consistent quality in smaller batches. It’s worth reflecting on past experiences with suppliers. Understanding your project’s specific needs can avoid future headaches. Each decision should be carefully analyzed to ensure long-term success.

| Glass Yarn Type | Diameter (μm) | Tensile Strength (MPa) | Thermal Stability (°C) | Refractive Index | Applications |

|---|---|---|---|---|---|

| Standard Glass Yarn | 9 | 2500 | 400 | 1.5 | Telecommunication Cables |

| High Strength Glass Yarn | 12 | 3000 | 450 | 1.49 | High Performance Cables |

| Low Loss Glass Yarn | 8 | 2800 | 500 | 1.48 | Data Transmission |

| Specialized Glass Yarn | 10 | 2600 | 480 | 1.47 | Specific Industrial Uses |