-

Home

-

Products

-

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

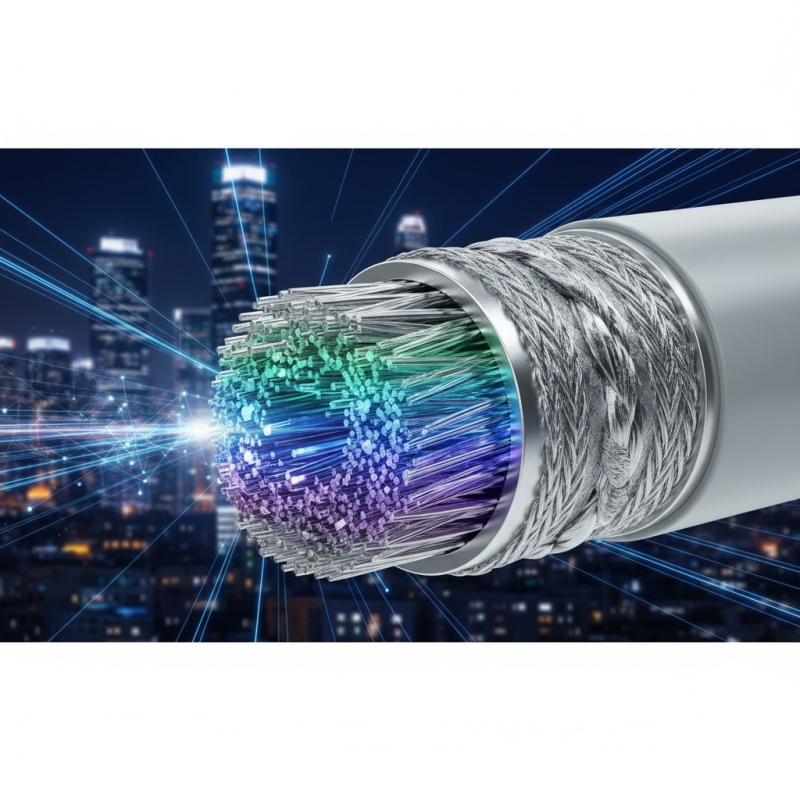

In the rapidly evolving world of telecommunications, the efficiency and durability of optical cables are paramount. As the demand for high-speed internet and data transmission continues to soar, manufacturers are seeking innovative materials that enhance performance while ensuring longevity. One such material gaining traction in 2023 is glass yarn for optical cables. This revolutionary addition offers numerous benefits that not only improve the physical properties of optical fibers but also address critical challenges faced by the industry.

Glass yarn for optical cables enhances mechanical strength, provides excellent resistance to environmental factors, and significantly reduces the weight of the cables, making installation easier and more efficient. Furthermore, its superior thermal stability ensures that optical fibers can maintain optimal performance even under extreme conditions. As we delve into the top five benefits of using glass yarn for optical cables, it becomes evident why this material is poised to reshape the landscape of telecommunications. Its unique properties not only support advanced technology but also align with the growing emphasis on sustainability and resource efficiency in cable manufacturing. By examining these advantages, industry stakeholders can better understand the potential impact of glass yarn in advancing optical communication systems.

Glass yarn is a composite material primarily made from silica, which is drawn into fine fibers that possess exceptional tensile strength and thermal resistance. The composition of glass yarn typically includes about 60%-70% SiO2, with other oxides such as Al2O3, Na2O, and CaO adding unique properties that enhance its performance in various applications. This structural integrity makes glass yarn an excellent choice for reinforcing optical cables, where durability and resistance to environmental factors are crucial.

According to recent industry reports, the demand for glass yarn in optical cable production is anticipated to grow considerably, driven by the surging need for high-speed data transmission and improved signal integrity. The Fiber Optic Industry Association (FOIA) estimated that the global market for optical fiber cables would reach approximately $7.5 billion by 2025, with glass yarn serving as a critical component due to its lightweight nature and ability to effectively manage heat dissipation. Furthermore, glass yarn's resistance to moisture and chemicals ensures that optical cables maintain their performance in diverse environments, making them suitable for both indoor and outdoor installations. This further solidifies glass yarn's position as a key material in advancing telecommunications infrastructure.

| Benefit | Description | Impact |

|---|---|---|

| Lightweight | Glass yarn is significantly lighter than traditional materials, reducing overall cable weight. | Easier installation and reduced shipping costs. |

| High Strength | Glass yarn exhibits excellent tensile strength, making it highly durable. | Increased lifespan of cables, reducing replacement frequency. |

| Thermal Stability | Resistant to temperature extremes, ensuring performance in harsh environments. | Reliable operation in diverse settings, enhancing application versatility. |

| Chemical Resistance | Not affected by moisture and many chemicals, preserving integrity. | Extended use in adverse conditions without degradation. |

| Enhanced Signal Clarity | Optical fibers made with glass yarn provide superior signal transfer. | Improved communication reliability and data transmission speeds. |

The integration of glass yarn in optical cables is revolutionizing the industry, particularly in enhancing the performance and reliability of these communication systems. Glass yarn offers superior strength and durability, providing an essential protective layer for the delicate fibers within optical cables. This enhancement minimizes signal loss and ensures optimal performance, especially in harsh environmental conditions. By reinforcing cables with glass yarn, manufacturers can deliver products that withstand tension and impact, making them ideal for both urban and remote installations.

When considering the use of glass yarn, it's beneficial to keep a few tips in mind. Firstly, ensure that the glass yarn is compatible with the specific types of fibers used in your optical cables to maximize efficiency. Additionally, pay attention to the manufacturing processes; a well-engineered cable that utilizes high-quality glass yarn can significantly extend the lifespan of your installation. Finally, remember to assess the environmental conditions of the installation site, as this will influence the choice of materials needed to achieve the best performance.

The trend toward using glass yarn continues to gain momentum, underscoring its effectiveness in improving optical cable performance. As the demands on communication networks grow in complexity, employing advanced materials like glass yarn will be vital for future-proofing infrastructure while ensuring high-speed data transmission and reliability.

The use of glass yarn in optical cables offers significant durability advantages, particularly in harsh environments. Glass yarn is inherently resistant to temperature fluctuations, moisture, and extreme weather conditions, making it an ideal material for outdoor and industrial applications. Unlike traditional materials, glass yarn maintains its integrity under various stressors, ensuring that the optical fibers within the cables remain protected and functional. This resilience means that optical cables reinforced with glass yarn are less likely to suffer damage from environmental factors, leading to reduced downtime and maintenance costs.

Additionally, glass yarn provides excellent tensile strength, which is crucial for optical cables that must withstand physical stress during installation and over their service life. Its lightweight nature combined with high performance allows for ease of handling and installation in challenging environments without sacrificing durability. The ability to resist wear and tear while maintaining flexibility makes glass yarn a superior choice for applications exposed to vibration, impact, or heavy loads. This enhances the overall reliability of optical communication systems, ensuring that they function optimally even in demanding conditions, thereby supporting the growing need for robust and steadfast connectivity solutions in various industries.

The growing demand for efficient and high-performance optical cables has led to significant advancements in materials used in their manufacturing. Among these, glass yarn has emerged as a cost-effective solution that enhances the durability and functionality of optical cables. By utilizing glass yarn, manufacturers can streamline production processes while maintaining high-quality standards. The lightweight nature of glass yarn not only contributes to reducing the overall material costs but also optimizes shipping and installation expenses, making it a practical choice for large-scale projects.

Moreover, glass yarn offers excellent mechanical properties, such as strength and resistance to environmental factors, which further translates into cost savings over time. The longevity and reliability of optical cables reinforced with glass yarn minimize the need for frequent replacements and repairs, ultimately reducing maintenance costs. As the industry continues to evolve, the integration of glass yarn in optical cable manufacturing presents a sustainable approach that balances performance with affordability, catering to the economic needs of both producers and consumers alike.

The use of glass yarn in optical cables represents a significant advancement in sustainable technology. Glass yarn, made from silica, is inherently more environmentally friendly than traditional materials like plastics. Its production involves fewer harmful chemicals, reducing the overall carbon footprint associated with manufacturing optical cables. Moreover, glass yarn is completely recyclable, providing an eco-friendly end-of-life option that aligns with modern sustainability efforts.

Tips for those considering glass yarn include researching local recycling options to ensure the material can be processed effectively. Additionally, when selecting optical cables, look for certifications that guarantee both product durability and environmental responsibility. This will not only ensure you are supporting sustainable practices but also enhance the longevity and performance of your optical cable installations.

Moreover, the lightweight nature of glass yarn reduces energy consumption during transportation, making it a more sustainable choice across the supply chain. Opting for glass yarn also helps diminish waste, as it is less likely to degrade over time compared to alternatives. By advocating for the use of glass yarn in optical technology, we can collectively contribute to a healthier planet while enjoying improved connectivity solutions.