-

Home

-

Products

-

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

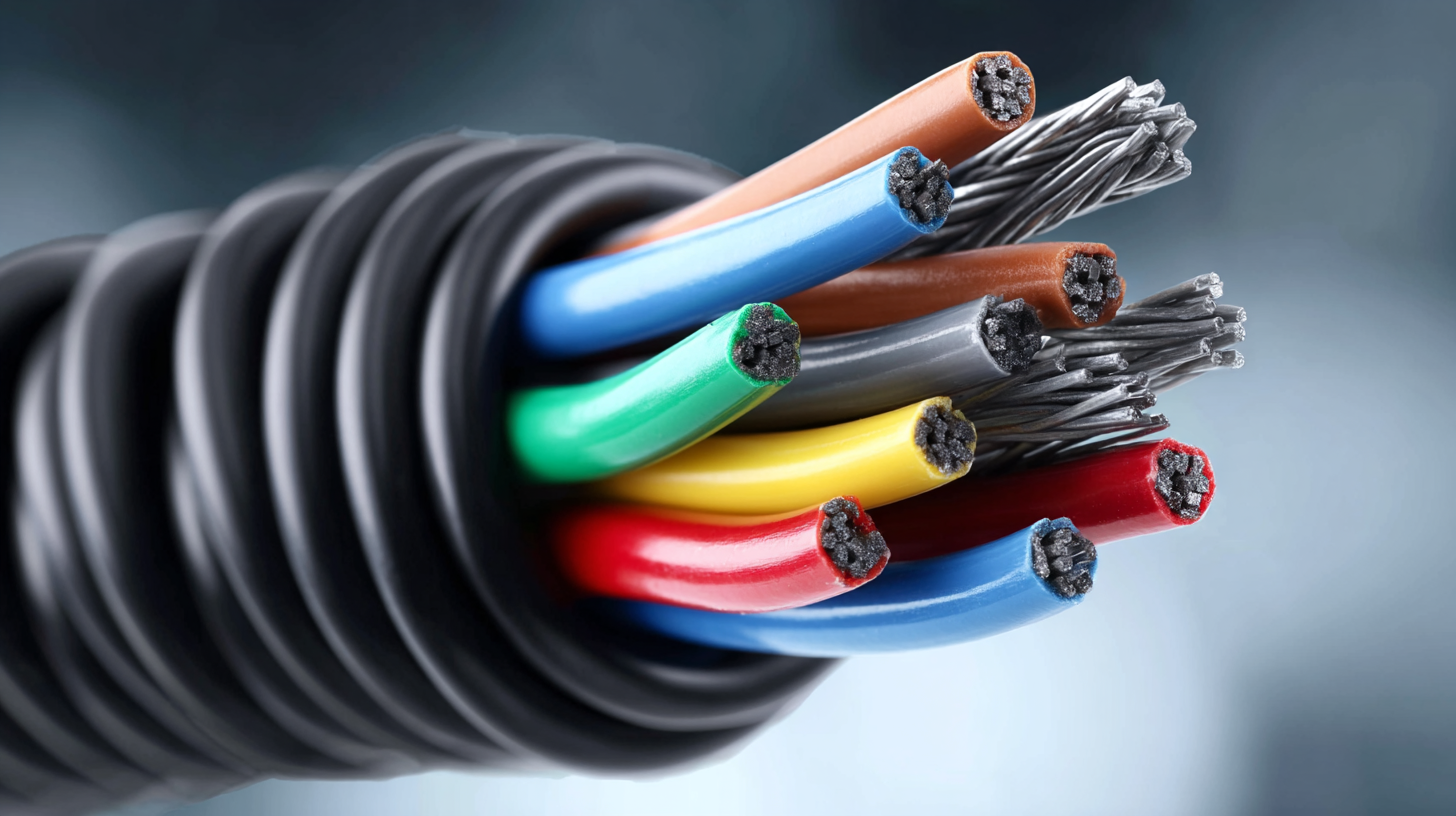

In the ever-evolving world of electrical installations, choosing the right materials is paramount for safety, efficiency, and longevity. Among the myriad options available, PVC cable material has emerged as a preferred choice due to its remarkable properties and benefits. Industry expert John Smith, a leading electrical engineer at Energy Solutions Inc., states, "The versatility and resilience of PVC cable material make it an indispensable asset in modern electrical applications."

From residential wiring to complex industrial setups, PVC cable material offers unmatched protection against environmental factors, excellent insulation capabilities, and cost-effectiveness. Its lightweight nature and flexibility allow for easier installation, making it a top choice for electricians and contractors alike. As we delve into the top seven benefits of using PVC cable material in electrical installations, it becomes evident how this material not only enhances performance but also contributes to a safer electrical landscape.

Polyvinyl chloride (PVC) cable material offers several advantages that significantly enhance electrical safety in various installations. One of the primary benefits is its inherent resistance to fire. PVC has a high ignition point and, when burned, produces minimal smoke and toxic fumes compared to other materials. This characteristic helps reduce the risk of fire spread, making PVC cables a preferred choice in residential and commercial buildings where safety is paramount.

Another critical aspect of PVC cable material is its excellent insulation properties. The material provides effective electrical insulation, reducing the chances of shorts and electrical failures. This function is crucial for protecting both equipment and personnel from potential electrical hazards. Furthermore, PVC cables are highly durable and resistant to wear, moisture, and corrosive substances, making them suitable for a variety of environments. Their longevity reduces the frequency of replacements, further enhancing safety by minimizing the chances of deterioration and subsequent failures over time.

When it comes to electrical installations, the choice of materials can significantly impact both the initial costs and long-term maintenance expenses. PVC (polyvinyl chloride) cable material stands out as a highly cost-effective option. Its durability and resistance to environmental factors ensure that installations can withstand the test of time without requiring frequent replacements or repairs. This long lifespan leads to substantial savings over time, making PVC a smart financial investment for both residential and commercial projects.

**Tips:** When selecting PVC cables, consider the specific environmental conditions they will be exposed to. For outdoor installations, ensure that the PVC is UV-resistant to prevent degradation. Additionally, look for products with a higher fire rating for added safety, which can further reduce long-term costs associated with potential hazards.

Another advantage of PVC is its low maintenance requirements. Unlike some alternative materials, PVC does not corrode or rust, which further reduces the need for repairs and upkeep. Additionally, its lightweight nature makes installation quicker and more straightforward, significantly cutting down on labor costs. By choosing PVC, not only do you save on materials, but you also streamline the installation process, maximizing efficiency from start to finish.

**Tips:** Always check manufacturer specifications for load capacity when planning your installation. Using high-quality connectors and fittings can also improve the overall performance and longevity of your electrical system.

| Benefit | Description | Long-Term Cost Implication |

|---|---|---|

| Cost-Effectiveness | PVC cables are generally less expensive compared to other materials, reducing initial installation costs. | Lower upfront costs can lead to significant savings when scaled in large projects. |

| Durability | PVC is resistant to abrasion, impact, and weathering, extending the lifespan of electrical installations. | Reduces the frequency of replacement and maintenance costs over time. |

| Lightweight | Easier handling and installation due to its lighter weight, reducing installation time and labor costs. | Saves on labor costs, especially for large-scale installations. |

| Chemical Resistance | PVC is resistant to many chemicals, making it suitable for diverse environments. | Lower risk of damage leads to long-term savings in repairs and replacements. |

| Fire Resistance | PVC has flame retardant properties, enhancing the safety of electrical installations. | Potentially lower insurance premiums due to reduced fire risk. |

| Versatility | Can be used in a wide range of applications, from residential to industrial. | Flexible options for various projects can lead to overall cost savings. |

| Low Maintenance | Requires minimal maintenance due to its durable nature, saving ongoing costs. | Reduced maintenance schedules mean lower long-term operational costs. |

PVC cables have emerged as a preferred choice in electrical installations due to their remarkable durability and longevity. Unlike other materials, PVC is resistant to harsh environmental conditions, including moisture, chemicals, and UV rays, which greatly reduces the risk of wear and tear over time. This resilience means that installations using PVC cables are less likely to experience downtime, ultimately leading to decreased maintenance costs and improved reliability in electrical systems.

When considering PVC cables for your projects, remember these tips: ensure that the cables conform to relevant safety standards and certifications to guarantee performance and reliability. Additionally, proper installation techniques are essential; using adequate supports and avoiding excessive bending can help maintain the integrity of the cables. Regular visual inspections can also alert you to any potential issues before they become significant problems, allowing for prompt corrective actions and extending the lifespan of your electrical installations.

PVC cable material stands out in electrical installations, particularly due to its exceptional environmental resistance. Unlike other materials that may deteriorate under harsh conditions, PVC maintains its integrity, making it ideal for applications exposed to extreme temperatures, moisture, and chemical exposure. This resilience ensures that electrical systems remain operational in various adverse environments, preventing potential failures that could arise from wear and tear.

With increasing attention on environmental impacts, it is noteworthy that PVC's durability also implies longer-lasting installations. This contrasts with efforts to phase out less durable plastic products, such as straws, which contribute to pollution. Innovations in PVC focus on maintaining performance while addressing environmental concerns. As research highlights the importance of selecting materials that withstand climate challenges, PVC emerges as a reliable choice for engineers and developers looking to ensure the longevity and safety of electrical installations in both traditional and harsh environments.

When it comes to electrical installations, the choice of cable materials significantly impacts both performance and ease of setup. PVC (Polyvinyl Chloride) has emerged as a top contender due to its inherent flexibility and user-friendly design. This flexibility allows installers to navigate through tight spaces and around obstacles without compromising the integrity of the wiring. The lightweight nature of PVC cables makes handling and installation considerably easier, reducing labor time and minimizing the physical strain on technicians.

Moreover, the simple design of PVC cables promotes quicker and more efficient installations. Their ability to be easily bent and twisted allows for creative routing, making it possible to adapt to various architectural layouts. This adaptability not only enhances efficiency during installation but also encourages safer practices, as improper cable routing can often lead to future maintenance issues. Overall, PVC cable material stands out in electrical projects due to its flexibility and ease of installation, ensuring that jobs can be completed smoothly and effectively.