-

Home

-

Products

-

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

Coaxial cables are vital in various applications, from telecommunications to broadcasting. The composition of the coaxial cable material significantly impacts its performance. According to a recent report by the International Telecommunication Union, 70% of network interruptions can be traced back to faulty materials in cabling systems.

Expert Jessica Thompson, a leading figure in the coaxial cable industry, stated, “The right materials can make or break signal quality and durability.” Choosing high-quality dielectric and shielding materials is essential for effective signal transmission. Common materials include polyethylene, PVC, and copper. Each option has strengths and weaknesses.

However, many manufacturers still overlook quality standards. This practice leads to inconsistent performance and reliability. Not every coaxial cable material guarantees optimal function in all environments. Users must carefully assess their needs. Ultimately, selecting the best materials can enhance signal clarity and reduce interference.

Coaxial cables consist of several key components. At their core, they have a central conductor that carries the signal. Surrounding this conductor is an insulating layer, usually made from materials like polyethylene. This insulation provides both protection and support. The next layer is the shield, often made from braided copper or aluminum foil. This shielding is critical for preventing interference from external sources.

The outermost layer of coaxial cables is the jacket. This layer offers durability and protects against environmental factors. According to industry reports, the choice of materials significantly impacts performance. For instance, cables with high-grade copper conductors can reduce signal loss and enhance transmission quality.

Tips: When choosing coaxial cables, consider the environment. Cables exposed to harsh weather need a tough outer jacket. Also, check for impedance matching; mismatched cables can lead to poor signal quality. Finally, always test the cables after installation. This step can prevent future issues and ensure optimal performance.

| Material Type | Purpose | Benefits | Drawbacks |

|---|---|---|---|

| Copper | Inner Conductor | Excellent conductivity, low resistance | Prone to oxidation, expensive |

| Aluminum | Inner Conductor | Lightweight, cost-effective | Higher resistance than copper |

| Polyethylene | Insulation | Good dielectric properties | Temperature sensitive |

| Foam Polyethylene | Insulation | Lower weight, improved signal quality | Less durable than solid polyethylene |

| PVC (Polyvinyl Chloride) | Outer Jacket | Durable, weather-resistant | Can become brittle over time |

| PE (Polyethylene) | Outer Jacket | Flexible, excellent moisture resistance | Less UV resistant than PVC |

Coaxial cables are essential for transmitting signals in various applications. Their construction involves several key materials, each playing a vital role in performance. The inner conductor, usually made of copper or aluminum, carries the signals. Copper is often preferred for its excellent conductivity. However, aluminum is lighter and more cost-effective.

The insulating layer is another important component. It’s commonly made from polyethylene or PVC. These materials help prevent signal loss and protect against external interference. Shielding is crucial as well. A layer of braided copper or aluminum foil surrounds the insulator. This shielding minimizes electromagnetic interference, enhancing signal clarity.

While these materials work well, there are considerations. Not all coaxial cables are the same. The choice of materials impacts flexibility and durability. Sometimes, even small variations can affect performance. Mistakes in material choice might lead to connectivity issues. Reflecting on your specific needs can guide better decisions. Choosing the right coaxial cable involves analyzing trade-offs and understanding material properties.

Coaxial cables are essential for transmitting signals with minimal loss. The materials used significantly impact performance. Among these, the dielectric material plays a crucial role in signal quality. Dielectric materials are insulators placed between the inner conductor and outer shield. Their properties affect the cable's ability to maintain signal integrity.

Materials like foam polyethylene provide low loss and high performance. However, their manufacturing process can create inconsistencies. Not every batch performs the same. Solid materials, while durable, may introduce higher losses. The choice depends on specific applications.

A good dielectric ensures lower signal attenuation. This is vital for long-distance transmission. Quality control is necessary to guarantee consistency. In real-world scenarios, even small imperfections can lead to significant issues. It’s essential to weigh the options wisely. Understanding the nuances of dielectric materials can lead to better decision-making in coaxial cable design.

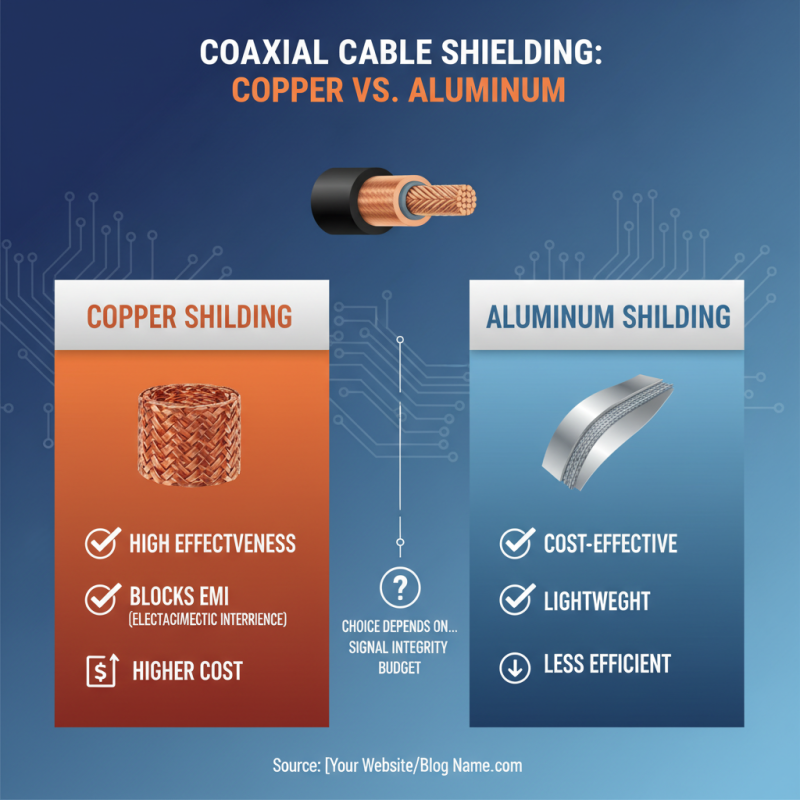

When it comes to coaxial cables, shielding material is crucial. The right material ensures signal integrity while minimizing interference. Copper and aluminum are the most common choices for shielding. Copper is highly effective in blocking electromagnetic interference, but it can be more expensive. Aluminum, while less efficient, offers a lightweight and cost-effective alternative.

A comparative analysis from industry reports shows that copper cables can reduce signal loss by up to 20% compared to aluminum ones. However, aluminum shields can still provide sufficient protection in many applications. The decision often boils down to application needs and budget constraints. Remember, the thickness of the shielding also affects performance. Thicker materials tend to perform better but may add weight and cost.

Tips: Always assess your requirements. For high-frequency applications, invest in better shielding materials. If you lean towards budget, a well-designed aluminum option might suffice. Reflect on your choices. It’s essential to weigh the pros and cons. Every project can benefit from a tailored approach to coaxial cable material selection. Pay close attention to detail; it can make a significant impact.

The future of coaxial cable materials shines brightly with innovative advancements on the horizon. Data from industry reports indicate a growing trend towards using lightweight, flexible materials that enhance performance and reduce installation costs. New compounds, such as thermoplastic elastomers, show promise for improved durability and conductivity.

A study by Research and Markets predicts a 5% CAGR in the coaxial cable market through 2027. This growth emphasizes the need for innovative materials that can handle higher frequencies while minimizing signal loss. Technologies like foam-dielectric and improved shielding are becoming essential. They help cater to the increasing demand for bandwidth and reliability.

Tips: Consider materials that can withstand harsh environments. Testing under different conditions can yield surprising results. Also, keep an eye on recyclability. Sustainable materials are not just a trend; they are becoming essential. Balancing performance with eco-friendliness is crucial in modern designs.