-

Home

-

Products

-

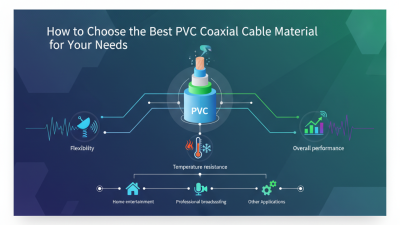

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

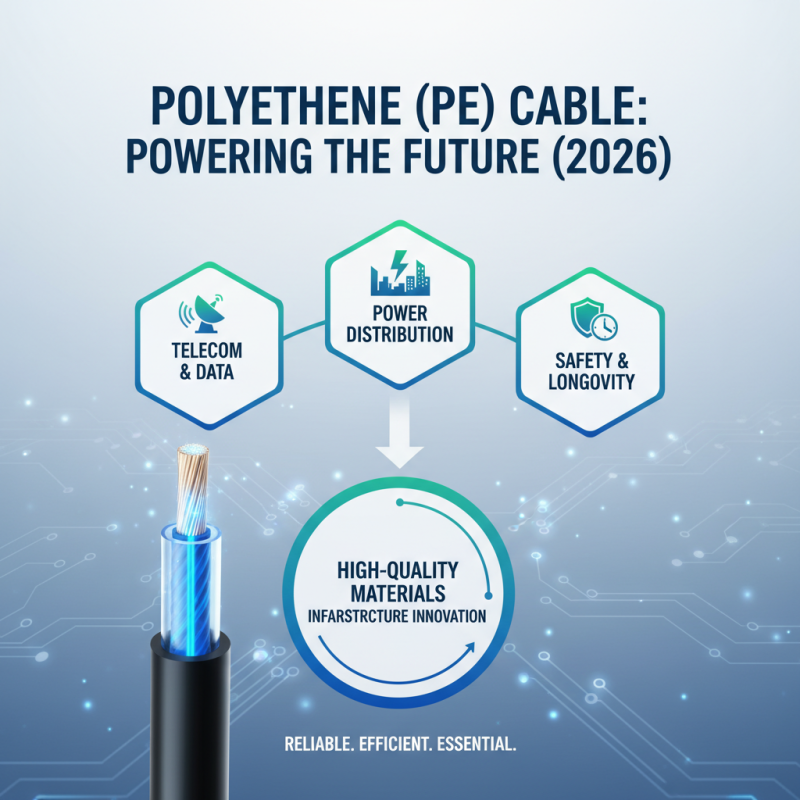

In 2026, the landscape of PE cable material is set to evolve significantly. Industry expert Dr. Emily Dawson notes, "The future of PE cable materials will focus on sustainability and efficiency." This statement encapsulates a growing trend among manufacturers and engineers.

As technology advances, the demand for high-performance, durable materials becomes crucial. Traditional options may not meet the efficiency standards required in modern applications. The need for innovative approaches is clear, as current materials can sometimes fall short. The push for greener alternatives also begs the question: are we truly ready to embrace change, or are we clinging to outdated practices?

The increasing complexity of electrical systems demands a reevaluation of our material choices. Factors such as temperature resistance, environmental impact, and cost-effectiveness are vital in this discussion. While we strive for perfection, imperfections remain in the materials we rely on. It's vital to reflect on whether our current PE cable materials can adapt to the needs of a rapidly changing industry.

Polyethylene (PE) cable is vital for various applications in 2026. It is used widely in telecommunications and power distribution. The demand for reliable and efficient materials has grown tremendously. This is due to innovations in technology and better infrastructure needs. High-quality PE cables ensure safety and longevity.

In 2026, factors like weather resistance and durability became crucial. Cables must withstand different environments. Flexible materials help adapt to changes in temperature. Enhanced UV protection is needed for outdoor installations. These features prevent degradation over time. However, manufacturers sometimes overlook these aspects when developing products. It's essential to reassess material choices continuously.

The importance of recycling cannot be ignored. As more cables are produced, waste increases. Selecting recyclable materials can minimize environmental impact. There is still a long way to go in achieving sustainability. Often, organizations prioritize functionality over eco-friendliness. A balance must be struck to ensure future success. It's a conversation worth having.

When designing PE cables in 2026, key properties of materials play a crucial role. Polyethylene (PE) remains popular due to its excellent insulation properties. This material shows resistance to moisture and various chemicals. These qualities make it ideal for outdoor applications.

Another important factor is flexibility. The best materials provide ample flexibility, preventing cracks during installation or use. A balance between strength and softness is essential. For instance, thicker insulation can improve durability but may reduce flexibility. Choose wisely based on the application.

Tips: Always test materials under simulated conditions before use. Regular inspections can catch issues early. Remember, the goal is to enhance longevity while maintaining performance. Optimal material choice leads to significant long-term savings. Reflect on potential improvements as technology evolves.

Emerging technologies in polyethylene (PE) cable materials are changing the landscape in 2026. Innovative compounds promise enhanced performance and durability. These new materials exhibit better resistance to heat and chemicals. This can lead to longer lifespan and less frequent replacements.

One key trend is the use of nanomaterials. They strengthen the overall structure of cables. This could improve flexibility while maintaining strength. Improved conductivity is also achieved, reducing energy loss in transmission. Next-generation PE cables may utilize bio-based alternatives. These materials aim to reduce environmental impact without sacrificing quality.

Tips: Always consider the wiring environment. Extreme conditions can affect material performance. Testing various scenarios is crucial. Understanding how new materials react over time is essential. Some may degrade faster than expected, leading to future concerns. In this evolving field, trial and error may be inevitable. Embrace the learning curve.

In 2026, the demand for efficient and durable PE cables continues to rise. The choice of materials is crucial. Traditional materials like polyethylene have been the norm for years. However, innovative alternatives are emerging. These materials promise better performance and sustainability.

Recent reports indicate that traditional polyethylene cables have limitations in thermal resistance and flexibility. On the other hand, newer composites are showing significant improvements. These composites can withstand higher temperatures and offer greater tensile strength. A study indicates that innovative materials can improve durability by up to 30%. This shift is essential for industries that require reliable connections.

Tips: When choosing materials, consider the environment. Innovation often leads to lower carbon footprints. Evaluate the long-term cost-effectiveness. Sometimes, the upfront expense of new materials pays off in the long run. However, not every new solution is perfect. Some may still require refinements or present challenges like sourcing sustainable raw materials.

While traditional options may seem safer, they might not meet growing industry standards. Explore innovative choices carefully. The balance between innovation and practicality is vital. The future of PE cables hinges on these material comparisons.

The environmental impact of polyethylene (PE) cables is a growing concern. In 2026, materials used in these cables will need to balance durability with eco-friendliness. Traditional PE materials often contribute to plastic waste, which is a significant issue. Innovations in biodegradable composites could significantly reduce this impact, but they are still in development.

Recycling efforts are crucial for PE cable sustainability. Recycling processes can be complex, often yielding only limited reuse opportunities. Communities need better infrastructure to handle these materials responsibly. Current methods sometimes create more pollution than they prevent. Additionally, awareness of sustainable practices is still lacking in many industries.

Emerging materials must also consider long-term environmental effects. Some alternatives may perform well initially but degrade quickly. This issue raises questions about long-term viability. Finding a balance between performance and sustainability is essential. As we look ahead, the choices made today will shape the environmental landscape of the future.