-

Home

-

Products

-

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

When it comes to setting up reliable communication systems, the importance of choosing the right PVC coaxial cable material cannot be overstated. PVC, or polyvinyl chloride, is a popular choice due to its excellent insulating properties, durability, and cost-effectiveness. However, not all PVC coaxial cable materials are created equal, and selecting the most suitable option for your specific needs requires careful consideration of various factors.

In the following sections, we will explore the intricacies of PVC coaxial cable material, examining key characteristics like flexibility, temperature resistance, and overall performance. Understanding these elements will empower you to make an informed decision that not only meets your current requirements but also ensures longevity and efficiency in your communication networks. Whether you're setting up a home entertainment system, a professional broadcasting environment, or any application that relies on coaxial cables, a thorough comprehension of the material will lead to optimal results.

When selecting PVC coaxial cable materials, it's essential to understand their basic components and properties. PVC, or polyvinyl chloride, is a widely used plastic in cable insulation and sheathing due to its durability and resistance to moisture, chemicals, and abrasion. The material's flexibility allows for easy installation in various environments while maintaining solid performance. PVC coaxial cables typically consist of a central conductor, an insulating layer, a shielding layer made of metallic foil or braided wire, and an outer PVC sheath, which offers additional protection.

Another crucial aspect of PVC coaxial cable materials is their capacitance and impedance characteristics, which can significantly impact signal transmission quality. The choice of dielectric material and the construction of the cable shield affect the cable's overall performance, particularly in high-frequency applications. Therefore, it's vital to consider the specific requirements of your project, such as the signal type, distance, and environmental factors, to select a cable that meets your needs effectively. Understanding the nuances of these materials will ensure you choose the best PVC coaxial cable for your applications.

When selecting PVC coaxial cables, it's essential to consider a few key factors to ensure they meet your specific needs. The first factor is the cable's intended application. Different applications, such as video transmission, telecommunications, or data networking, will have varying requirements in terms of frequency range and attenuation. Understanding the demands of your project will guide you in choosing a cable that can deliver optimal performance.

Another crucial aspect is the cable's construction and materials. Look for cables with a solid copper core, as this will provide better signal quality compared to copper-clad aluminum. Additionally, consider the shielding used in the cable; a higher percentage of shielding will help minimize interference from external factors, ensuring a clearer signal transmission.

**Tip:** When evaluating PVC coaxial cables, check the manufacturer's specifications for impedance and attenuation rates, as these will greatly influence signal integrity.

Lastly, the environmental conditions in which the cable will be installed must be taken into account. If the cable will be placed outdoors or exposed to extreme temperatures, UV-resistant and weatherproof PVC materials will be necessary to prolong its lifespan.

**Tip:** Always verify if the cable complies with relevant safety and performance standards to guarantee quality and reliability in its intended environment.

When selecting PVC coaxial cable insulation, it's essential to understand the differences among various types to determine which best suits your specific application. PVC (Polyvinyl Chloride) insulation is favored in many industries for its superior dielectric strength and resistance to environmental factors. According to a report by the International Electrotechnical Commission, cables with PVC insulation provide excellent performance under temperature fluctuations, withstanding extremes from -20°C to 70°C, making them ideal for both indoor and outdoor installations.

Different formulations of PVC can also offer varying levels of flexibility and durability. For instance, some shielded PVC cables combine PVC with other materials to enhance their resistance to abrasion and chemicals. A study by the Institute of Electrical and Electronics Engineers indicates that cables with enhanced PVC insulation can reduce signal loss by up to 25% compared to standard types, thus improving overall transmission quality. Additionally, certain PVC compounds are designed to be halogen-free, which is crucial for reducing toxic gas emissions in case of a fire.

Choosing the right type of PVC insulation ultimately hinges on understanding the specific environmental and performance demands of your application. By analyzing the physical and chemical properties, such as tensile strength and temperature tolerance, you can ensure the selected insulation not only meets regulatory standards but also enhances the longevity and reliability of your coaxial cable installation.

When selecting PVC coaxial cable, it is crucial to evaluate its electrical performance and signal quality to ensure optimal functionality for your specific application. The dielectric material's properties significantly influence the cable's ability to transmit signals with minimal attenuation. A high-quality dielectric helps reduce losses, which is particularly important for long-distance transmissions where even minor signal degradation can lead to substantial quality issues. Assessing the cable's capacitance and its maximum frequency rating allows users to gauge how well the cable will perform under different operating conditions.

Additionally, the shielding of the coaxial cable plays a vital role in maintaining signal integrity. A well-designed shield protects against electromagnetic interference (EMI) and minimizes noise pickup, which is essential for applications requiring high fidelity such as video transmission or data communication. Evaluating the material and thickness of the shield will directly impact performance; for example, foiled or braided shields generally provide better protection than simple foil shields. By carefully considering these factors, one can select a PVC coaxial cable that not only meets the electrical specifications needed but also delivers superior signal quality for reliable and efficient operation.

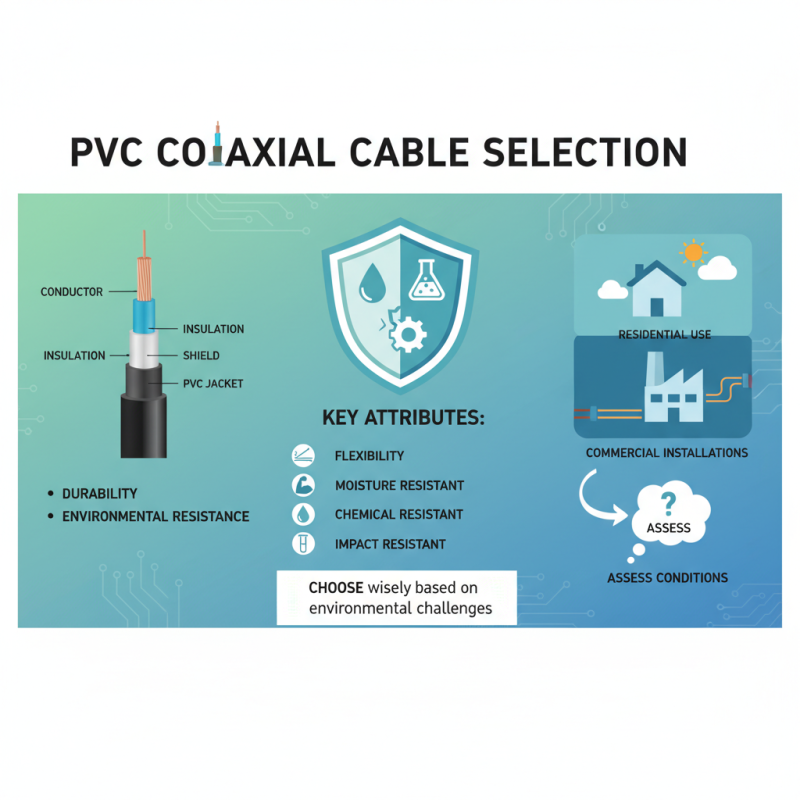

When choosing PVC coaxial cable, it’s essential to assess the durability and environmental resistance of the materials involved. PVC, or polyvinyl chloride, is a popular choice due to its balance of flexibility and strength. This material is notably resistant to certain impacts, moisture, and many chemicals, making it suitable for various applications, from residential uses to commercial installations. However, not all PVC cables are created equal, and understanding the specific environmental conditions they will face is critical.

Tips: When selecting PVC coaxial cable, consider the local climate and potential exposure to environmental elements. For instance, if the cable will be used outdoors, look for UV-resistant formulations to prevent degradation from sunlight. Additionally, if you're in an area prone to extreme temperatures, choose cables that can withstand both heat and cold without compromising performance.

Another factor to keep in mind is the cable's resistance to chemicals. Some PVC cables may be vulnerable to specific substances, which can lead to premature failure. Conducting a thorough assessment of the environment in which the cable will be installed can help you choose a product that maintains its integrity and functionality over time. Always check for certifications or testing results that demonstrate a cable’s durability against the conditions it will encounter.