-

Home

-

Products

-

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

In the rapidly evolving solar energy sector, the selection of appropriate Photovoltaic Insulation Cable Materials has become crucial for ensuring optimal solar panel performance. According to a recent report by the International Renewable Energy Agency (IRENA), the global solar energy capacity is expected to grow by over 800 gigawatts by 2025, highlighting the increasing demand for reliable solar infrastructures. As more installations come online, the need for specialized materials that can withstand varied environmental conditions while maintaining high efficiency is more important than ever.

Expert in photovoltaic technology, Dr. Emily Chen, emphasizes the significance of this choice: “The right Photovoltaic Insulation Cable Material can mean the difference between a system that operates at peak efficiency and one that is derated by weather or environmental factors.” Selecting a high-quality insulation cable not only enhances the overall durability of solar power systems but also contributes to the longevity of the equipment, ultimately driving down maintenance costs and improving return on investment for solar energy projects.

As we delve into the top 10 considerations for choosing the right Photovoltaic Insulation Cable Material, we will explore the various properties, certifications, and performance metrics that are essential for maximizing solar panel efficiency and ensuring the longevity of your solar energy investments. Making informed decisions in this area can significantly impact not just the performance of solar panels, but the broader sustainability goals we aim to achieve in the fight against climate change.

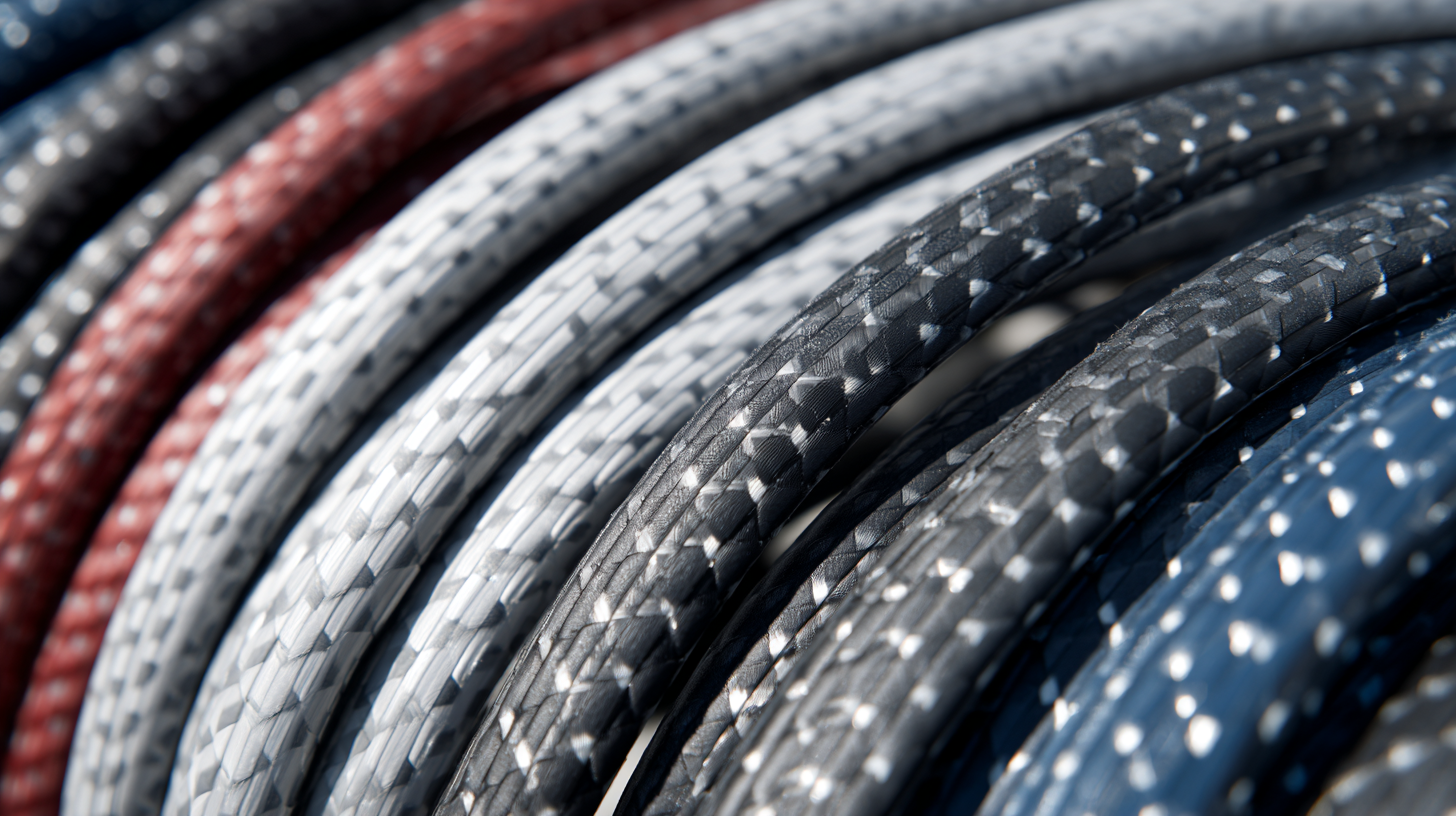

When selecting the right photovoltaic insulation cable material, several critical factors must be considered to ensure optimal solar panel performance. The performance and durability of solar installations depend heavily on the quality of wiring solutions, which are projected to experience significant growth in the U.S. wires and cables market, expected to expand from $33.49 billion in 2025 to $49.76 billion by 2032. This surge reflects an increasing emphasis on renewable energy sources, illuminating the importance of selecting appropriate materials that meet stringent performance standards.

Key considerations include the thermal behavior of cable materials under operational stress, especially in high-temperature environments typical for solar applications. For instance, materials must withstand variations in thermal expansion and maintain insulation integrity to ensure long-term efficiency. Furthermore, comparing materials like aluminum and copper highlights differing electrical properties and cost efficiency, indicating that the right choice for photovoltaic cables contributes significantly to the overall effectiveness of solar panel systems. As the renewable energy sector expands, understanding these factors is essential for maximizing the potential of solar technologies.

When choosing insulation materials for photovoltaic applications, it's essential to understand the comparative advantages of commonly used types. Materials such as fiberglass, ceramic, and calcium silicate insulation sleeves offer unique benefits that can significantly impact the performance and longevity of solar panels. For instance, fiberglass sleeves provide excellent heat resistance and mechanical strength, making them suitable for high-temperature environments. In contrast, ceramic insulation offers superior durability and chemical resistance, making it ideal for harsh outdoor conditions. Calcium silicate, known for its thermal insulation properties, is also gaining traction in flexible photovoltaic systems, contributing to better energy efficiency.

Recent advancements in solar technologies emphasize the importance of effective insulation in maximizing performance. As flexible perovskite solar cells gain popularity, researchers highlight that surface defects and moisture intrusion can detrimentally affect device efficiency and stability. Advancements in insulation materials, therefore, not only enhance the operational efficiency of photovoltaic panels but also mitigate environmental factors that could compromise their functionality. As the solar industry continues to grow, selecting the right insulation material will play a pivotal role in the overall efficiency and reliability of solar energy systems.

The efficiency of solar panels is significantly influenced by the choice of photovoltaic insulation cable materials. Recent studies show that cables with superior thermal and electrical properties can minimize energy losses, thereby enhancing overall solar panel performance. Traditional copper cables continue to dominate due to their excellent conductivity; however, innovations in materials such as super crystalline nanomaterials are showing promise in the photovoltaic sector. These advanced materials reduce resistance losses and improve durability, which are critical for maintaining efficiency under varying environmental conditions.

Furthermore, as the emphasis on renewable energy sources grows, understanding the material impact becomes crucial. According to the International Renewable Energy Agency (IRENA), integrating high-quality cable materials can lead to efficiency gains of up to 10% in solar installations. This is particularly important as solar technology evolves, with perovskite materials emerging as potential game-changers. Research indicates that the right choice of cable insulation not only contributes to the longevity of solar systems but also plays a pivotal role in achieving more sustainable energy outcomes, directly influencing the market growth for photovoltaic technologies.

When installing photovoltaic insulation cables, it is crucial to adhere to best practices to ensure optimal performance and longevity of the solar panel system. First, select high-quality materials that can withstand environmental stressors such as UV radiation, extreme temperatures, and moisture. Utilizing cables designed specifically for photovoltaic applications will enhance durability and reduce the risk of degradation over time. Proper insulation will prevent energy loss and ensure safety by minimizing the risk of electrical hazards.

In addition to choosing the right materials, installation techniques play a vital role in maintaining the integrity of photovoltaic insulation cables. Ensure that cables are laid out in a manner that avoids sharp bends and kinks, which can damage the insulation. Utilize appropriate mounting solutions to secure cables away from potential abrasion points and to protect them from mechanical damage. Regular inspection is also necessary; check for any signs of wear or deterioration, and address issues promptly to prevent performance decline. Following these best practices not only enhances solar panel efficiency but also contributes to the overall safety of the installation.

| Material Type | Thermal Resistance (°C) | UV Resistance | Flexibility Rating | Cost per Meter ($) |

|---|---|---|---|---|

| Cross-linked Polyethylene (XLPE) | 90 | Excellent | High | 1.50 |

| Polyvinyl Chloride (PVC) | 70 | Good | Moderate | 0.80 |

| Thermoplastic Elastomer (TPE) | 80 | Good | Very High | 1.20 |

| Polypropylene (PP) | 80 | Excellent | High | 1.00 |

| Flame-Retardant Polyvinyl Chloride (FR-PVC) | 70 | Good | Moderate | 0.90 |

The future of photovoltaic cable materials is set to evolve significantly, driven by technological advancements and increasing demand for enhanced solar performance. Recent reports from the International Renewable Energy Agency (IRENA) indicate that the solar market is expected to grow by over 20% annually through 2025, necessitating innovations in materials to support this burgeoning industry. Emerging materials, such as cross-linked polyethylene (XLPE) and thermoplastic elastomers, promise greater durability and efficiency, thus maximizing energy output.

Additionally, research from the Solar Energy Industries Association (SEIA) highlights the importance of resistance to extreme weather conditions. With climate change posing challenges like more intense storms and fluctuating temperatures, future cable materials will need to exhibit improved UV protection and moisture resistance. Advanced coatings and insulation technologies are being developed to enhance the longevity and performance of photovoltaic systems, which could ultimately lead to a reduction in maintenance costs and an increase in overall energy capture. As these trends gain traction, manufacturers and developers must stay informed and prioritize the integration of these innovative materials to ensure optimal solar performance in the coming years.