-

Home

-

Products

-

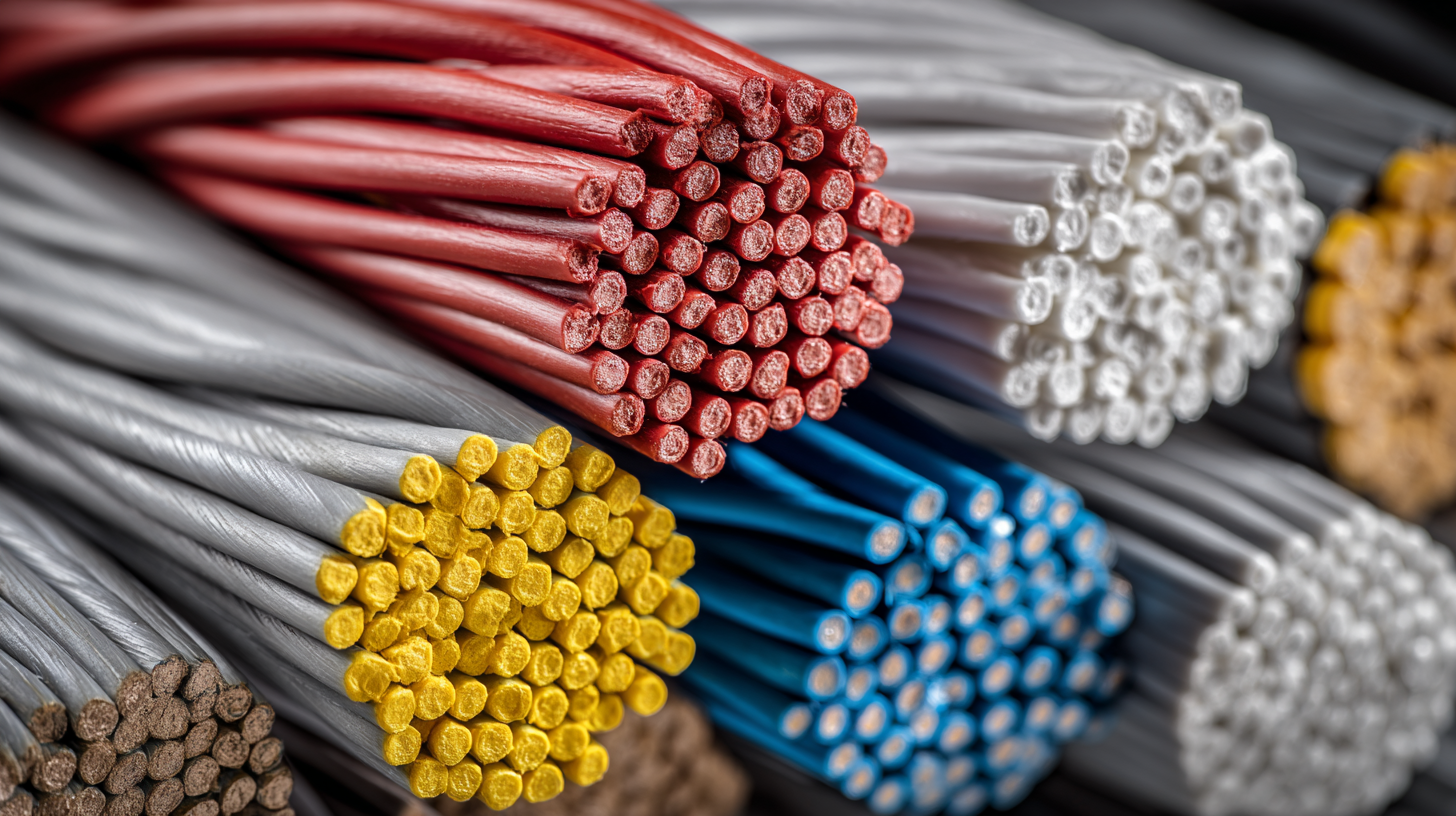

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

Choosing the right PVC cable material is crucial for ensuring optimal electrical performance in various applications, from residential wiring to industrial machinery. With a multitude of options available, including variations in thickness, flexibility, and chemical resistance, it can be overwhelming to determine which type best meets your specific needs. Understanding the fundamental properties of PVC cable material, such as its conductivity, insulation capabilities, and durability, is essential for making an informed decision.

Additionally, considering factors like environmental conditions, installation requirements, and compliance with safety standards can significantly influence the performance and longevity of electrical systems. This guide will provide valuable insights into the selection process, empowering you to choose the most suitable PVC cable material that aligns with your project's demands while maximizing efficiency and safety.

When selecting the right PVC cable material for electrical applications, it's essential to understand the different types available in the market. The global PVC market, valued at $67.89 billion in 2023, is projected to grow to $96.32 billion by 2031, at a compound annual growth rate (CAGR) of 4.53%. This substantial growth reflects a rising demand across various sectors, including construction, automotive, electrical and electronics, healthcare, and more. Each of these applications necessitates specific PVC formulations to ensure optimal performance and compliance with industry standards.

Within the PVC segment, rigid PVC and flexible PVC are the primary types utilized for electrical cabling. Rigid PVC, known for its sturdiness, is frequently utilized in fixed installations, whereas flexible PVC's adaptability makes it ideal for movable applications. As noted in the industry reports, the wire and cable materials market is also projected to expand significantly, with a focus on insulated products like PVC, which serve crucial roles across telecommunications and distribution networks. Specifically, TC and TC-ER cables, rated for up to 600 V, represent a significant portion of the anticipated growth, highlighting the importance of choosing the right materials for both safety and efficiency.

When selecting the right PVC cable material, several key factors significantly influence electrical performance.

One of the primary considerations is the aging characteristics of the cable insulation.

Over time, exposure to environmental stressors can degrade the insulation, leading to increased resistance and potential failures.

Implementing a reliable Aging Law and Life Evaluation Model, such as WOA‐SVR, can help predict the longevity and reliability of cable insulation, thereby optimizing overall performance.

Another crucial aspect is the thermal properties of the PVC material used.

The quality of insulation directly impacts the thermal stability of underground power cables, which, in turn, plays a vital role in their operational life.

The insulation must withstand high temperatures without compromising electrical performance. Additionally, the choice of additives and compounds in the PVC formulation can enhance the electrical characteristics, offering improved performance in telecommunications and other applications.

By addressing these factors, manufacturers can ensure that their PVC cables meet the demands of modern electrical systems.

When selecting the right PVC cable material, evaluating temperature resistance and flexibility is crucial for ensuring optimal electrical performance. Temperature resistance is important as it determines how well the cable can withstand extremes without degrading. PVC cables typically come with a range of temperature ratings, often spanning from -40°C to +70°C. When choosing a cable, it's essential to consider the environmental conditions it will face in its application, whether it's outdoor exposure or industrial settings with fluctuating temperatures.

Flexibility is another vital factor, especially in applications where the cable will be bent or moved frequently. A more flexible PVC cable can minimize the risk of damage and extend the lifespan of the installation. When selecting a cable, consider its thickness and the internal conductor design, as a well-engineered design enhances flexibility without compromising performance.

**Tips:** Always check the manufacturer's specifications for both temperature ratings and flexibility. For outdoor applications, opt for cables designed specifically for UV resistance to extend their life. Additionally, conduct flexibility tests on sample cables, if possible, to ensure they meet the demands of your specific installation.

When selecting PVC cable materials for electrical applications, assessing durability and chemical resistance is crucial for ensuring optimal performance. The environment in which the cable will be used significantly influences its longevity; thus, understanding the specific conditions—such as exposure to moisture, UV light, and temperature fluctuations—can help inform the selection process. For instance, cables that feature additional UV stabilizers or are designed with higher flexibility can endure harsh outdoor conditions, extending their life expectancy and maintaining safety standards.

In addition to environmental factors, chemical resistance plays a vital role in the selection of PVC cables. Different applications may expose cables to various chemicals, including oils, solvents, and corrosive substances. It is essential to review the material specifications and testing data provided by manufacturers to gauge how well a particular PVC formulation can withstand such exposures. Accordingly, choosing the right combination of additives and stabilizers can enhance the cable's resistance, ensuring reliable performance in even the most challenging conditions.

When sourcing PVC cable materials for electrical applications, it's imperative to adhere to best practices that guarantee optimal performance and durability. According to a report by MarketsandMarkets, the global PVC cable market is anticipated to reach approximately $31 billion by 2026, highlighting the increasing demand for high-quality materials. Key considerations include the chemical composition of the PVC; formulations with additives that enhance electrical insulation and resistance to environmental factors are crucial for maintaining performance in various conditions.

Testing plays a pivotal role in confirming the suitability of PVC materials. The International Electrotechnical Commission (IEC) provides standardized testing methods such as IEC 60227, which assess the dielectric properties and thermal stability of insulated cables. Suppliers should provide certification documents confirming compliance with these standards, ensuring that the materials can withstand not only electrical stress but also physical and thermal stresses typical in real-world applications. Investing in rigorous sourcing and testing processes ultimately reduces failure rates and enhances the reliability of electrical installations.