-

Home

-

Products

-

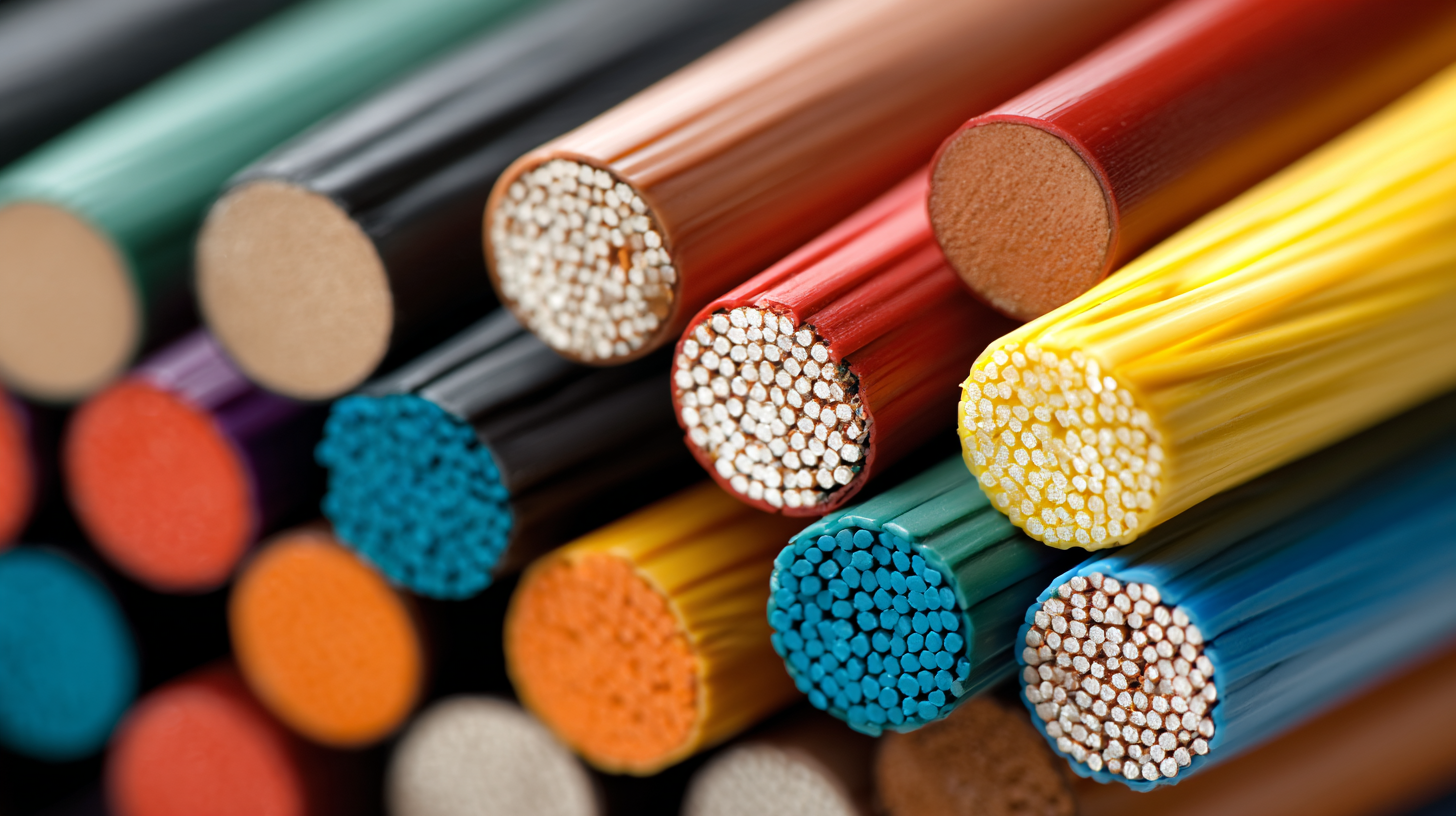

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

As the demand for safer electrical installations continues to grow, the choice of materials plays a crucial role in enhancing electrical safety. One standout solution is the use of Lszh Irradiated Insulating Cable Material, which offers significant advantages over traditional insulating materials. According to a recent report by [Industry Safety Insights], electrical fires account for approximately 23% of all fire incidents globally, highlighting the urgency for improved insulation solutions. With Lszh materials, operational characteristics such as low smoke production and halogen-free properties contribute to both safety and environmental considerations, making them increasingly popular in sectors like construction and telecommunications. This blog aims to provide key insights and data on how Lszh Irradiated Insulating Cable Material can be effectively utilized to elevate electrical safety standards, reduce risks, and ensure compliance with international safety regulations.

LSZH (Low Smoke Zero Halogen) irradiated insulating cable materials have become essential in enhancing electrical safety, particularly in environments where fire hazards are a significant concern. These materials are designed to emit minimal smoke and no halogen when subjected to fire, which significantly reduces toxicity and improves visibility during an emergency evacuation. According to the International Electrotechnical Commission (IEC), the use of LSZH materials in cable insulation can decrease the risk of smoke inhalation by up to 60%, making them a preferred choice for public transport systems, high-rise buildings, and industrial applications.

LSZH (Low Smoke Zero Halogen) irradiated insulating cable materials have become essential in enhancing electrical safety, particularly in environments where fire hazards are a significant concern. These materials are designed to emit minimal smoke and no halogen when subjected to fire, which significantly reduces toxicity and improves visibility during an emergency evacuation. According to the International Electrotechnical Commission (IEC), the use of LSZH materials in cable insulation can decrease the risk of smoke inhalation by up to 60%, making them a preferred choice for public transport systems, high-rise buildings, and industrial applications.

Data from the International Cablemakers Federation (ICF) indicates that the global market for LSZH cables is projected to grow at a compound annual growth rate (CAGR) of 9% over the next five years, driven by an increasing demand for fire-safe and environmentally friendly electrical solutions. Furthermore, LSZH irradiated insulating materials offer improved mechanical and thermal properties, with radiation cross-linking enhancing their strength and resistance to degradation. This means LSZH cables not only ensure safety but also provide long-term reliability in challenging operational environments, making them a valuable investment in electrical infrastructure.

When it comes to electrical safety, choosing the right materials can make all the difference.

LSZH (Low Smoke Zero Halogen) irradiated insulating cable materials are increasingly recognized for their significant safety benefits. Unlike traditional insulating materials,

LSZH cables emit minimal smoke and toxic gases when subjected to fire. This property is crucial in emergency situations, as it allows for better visibility and

reduces inhalation risks for individuals in the vicinity.

Another key advantage of LSZH materials is their superior thermal stability and mechanical durability. These features not only contribute to longer service life but also ensure that the cables maintain their insulating properties under harsh environmental conditions. This makes LSZH cables an excellent choice for various applications,

including public spaces such as airports, train stations, and commercial buildings, where both safety and performance are paramount.

By opting for LSZH irradiated insulating materials, industries can take a proactive step toward enhancing electrical safety and minimizing risks associated with cable installations.

When considering electrical safety and performance, a comparative analysis of LSZH (Low Smoke Zero Halogen) irradiated insulating cable materials against traditional insulating materials reveals some crucial insights. Traditional cables often release harmful halogens when exposed to fire, subsequently producing toxic smoke that poses serious health risks. In contrast, LSZH materials significantly reduce smoke generation and eliminate toxic fumes, making them a superior choice for environments where safety is paramount. According to a report by the International Institute of Electrical Engineering, LSZH cables can reduce smoke emissions by up to 90% compared to their halogen counterparts.

Tips for selecting the right insulating material include assessing the environmental conditions where the cable will be installed. For instance, in high-density public areas like transportation hubs or theaters, using LSZH cables is not just a recommendation but a necessity for ensuring public safety. Additionally, verifying the certification of materials is essential; look for compliance with international safety standards such as IEC 60332-3 for flame propagation.

Moreover, cost-effectiveness is another important factor. While LSZH cables may have a higher upfront cost, their long-term benefits, including lower maintenance costs and reduced health hazards, make them a wise investment. Always consult with industry guidelines and reports before making a decision, ensuring that the selected materials align with both safety standards and environmental considerations.

| Property | LSZH Irradiated Insulating Material | Traditional Insulating Material |

|---|---|---|

| Flame Retardancy | Excellent (low smoke and zero halogen) | Good (may produce toxic fumes) |

| Temperature Range | -40°C to +90°C | -20°C to +70°C |

| Dielectric Strength | 20 kV/mm | 15 kV/mm |

| Environmental Resistance | High (UV, moisture resistance) | Moderate (limited environmental stress resistance) |

| Mechanical Strength | Strong (higher flexibility and tensile strength) | Good (less flexible) |

| Lifecycle Cost | Higher initial cost but lower maintenance | Lower initial cost but higher maintenance costs |

In recent years, the adoption of LSZH irradiated insulating cable materials has significantly improved electrical safety in various real-world applications. These cables are particularly effective in environments where fire hazards are a concern, such as nuclear power plants and warehouses. Studies indicating that cable fires pose severe risks in these settings highlight the importance of selecting the right insulating materials. By utilizing LSZH irradiated cables, organizations can ensure a higher level of protection against potential fire incidents.

Tip: When selecting cables for critical applications, consider the environment in which they will be used. LSZH irradiated cables not only reduce smoke and toxic gas emissions during fires but also maintain their integrity under extreme conditions, making them a reliable choice for safety-conscious projects.

Moreover, the ongoing advancements in cable technology, including fire-retardant coatings, have shown promising results in reducing the dynamic risks associated with cable fires. By integrating these innovations with LSZH materials, industries can create a more robust fire safety environment.

Tip: Regularly assess your electrical infrastructure and ensure compliance with safety regulations. Implementing LSZH irradiated cables can be a proactive step towards mitigating fire risks and enhancing overall electrical safety in various applications.

When implementing LSZH (Low Smoke Zero Halogen) cables in electrical installations, several best practices can significantly enhance safety and performance.

First, it is crucial to assess the specific environment where the cables will be used. LSZH materials are particularly advantageous in confined spaces like tunnels or high-rise buildings, where smoke and toxic emissions from burning cables can pose severe hazards. Conducting a thorough risk assessment will help in selecting the appropriate LSZH cable type that meets the safety standards required for the installation.

First, it is crucial to assess the specific environment where the cables will be used. LSZH materials are particularly advantageous in confined spaces like tunnels or high-rise buildings, where smoke and toxic emissions from burning cables can pose severe hazards. Conducting a thorough risk assessment will help in selecting the appropriate LSZH cable type that meets the safety standards required for the installation.

Another important practice is to ensure proper installation techniques are followed. It is essential to avoid pinching or twisting the cables during the installation process, as this could compromise their integrity and safety. Additionally, using suitable connectors and termination methods designed for LSZH cables will help maintain their fire-resistant properties. Regular training for electricians and personnel involved in the installation is also advised to ensure they are familiar with the unique characteristics of LSZH cables and understand the potential challenges they may face. Adopting these best practices not only enhances electrical safety but also contributes to a safer environment for everyone involved.