-

Home

-

Products

-

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

In the evolving world of telecommunications, the use of Glass Yarn for optical cables has gained significant attention. Dr. Emily Thompson, a leading expert in fiber optics, once stated, "Glass yarn brings unmatched strength and flexibility to optical cables." This highlights the importance of understanding how to effectively employ glass yarn in this field.

Glass yarn not only enhances the durability of optical cables, but it also impacts their performance. Utilizing it correctly requires careful consideration of various factors, such as tensile strength and environmental conditions. Many companies overlook these aspects, leading to flawed cable design. Moreover, while glass yarn might seem straightforward, the nuances of its application can often be perplexing.

Designers often face the challenge of balancing strength and flexibility. This balance can affect the cable's longevity and reliability. Embracing these complexities is essential for achieving optimal results in optical cable production. By gaining insight into these critical aspects, we can unlock the full potential of glass yarn in telecommunications.

Glass yarn is an essential component in optical cable applications. Its lightweight and high tensile strength make it ideal for protecting delicate fibers. This material provides excellent insulation, which is critical in minimizing signal loss. The transparency of glass yarn also allows for clear visibility of the fibers during installation and repair.

Moreover, glass yarn is resistant to heat and chemicals, making it suitable for various environments. It can withstand harsh conditions, ensuring the longevity of the cable. However, it can be brittle, leading to challenges in handling. If mishandled, even the strongest glass yarn may break. Technicians need to be careful during installation to avoid potential damage.

Another important property is its moisture resistance. This helps protect the optical fibers from humidity and water damage. Nonetheless, the application of glass yarn should be periodically reviewed. Regular assessments help identify wear and tear before problems arise. While glass yarn provides many benefits, awareness of its limitations is vital for optimal performance in optical cables.

When selecting the right type of glass yarn for optical cables, consider the application. Different projects require different types. Do you need flexibility? Look for yarns specifically designed for tight bends. For outdoor use, ensure the glass yarn can withstand harsh conditions.

Here are some tips to guide your selection:

Choosing the right type is crucial and can sometimes be confusing. Consider consulting with experts or conducting trials. Experiment with samples to see how they perform in your setup. This process might take time, but it's worth it for reliable results. Adjusting your choice based on real-world testing can lead to better outcomes in your project.

Proper handling and storage of glass yarn are crucial for optimal performance in optical cables. One essential tip is to maintain a controlled environment. Temperature and humidity can significantly affect the integrity of glass yarn. Keeping the yarn in a dry area reduces the risk of damage. Avoiding extremes in temperature can also help maintain its quality.

When storing glass yarn, use dedicated containers. Clear bins allow for easy visibility while preventing dust accumulation. Labeling is important. You want to know what you have at a glance. Ensure that the containers are not tightly sealed, allowing for ventilation.

Another important aspect is careful handling during installation. Wear gloves to protect both the yarn and your hands. Contact with oils from skin can lead to performance issues later on. Keep workspaces organized. Clutter can lead to accidents and damage. Take the time to reassess your setup if things feel chaotic. Small lapses can turn into big issues down the line.

Incorporating glass yarn into optical cable design can enhance performance and durability. Glass yarn acts as a protective layer, adding tensile strength. This design choice is crucial in environments with high mechanical stress.

When integrating glass yarn, consider its placement carefully. Ensure it aligns with the cable's mechanical requirements. Proper layering can prevent damage to internal fibers. Different configurations can lead to varying results. Trial and error may reveal optimal methods.

Technique matters. Using short lengths of glass yarn can increase flexibility. However, excessively short strands might reduce structural integrity. Striking a balance is essential. Experiment with different yarn thicknesses, too. Thicker yarn offers more protection but may limit flexibility. Adapt your design based on the intended application of the cable. Each choice has implications that require careful reflection.

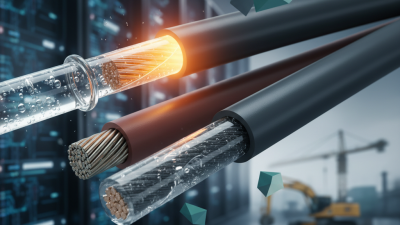

Testing and quality assurance of glass yarn in optical cables is vital. The performance of these cables hinges on the quality of materials used. According to a recent industry report, over 30% of optical cable failures can be traced back to inadequate testing procedures. This underlines the importance of rigorous quality checks throughout production.

Using standardized testing methods is essential. Single-mode and multi-mode fibers need to pass specific metrics like insertion loss and return loss. A report in the Journal of Optical Fiber Technology highlights that routine testing reduces failure rates significantly. Furthermore, evaluating the thermal endurance of glass yarn is crucial. The materials must withstand extreme temperatures without losing integrity.

Visual inspections play a key role too. Microscopic cracks or imperfections can affect transmission quality. Yet, many manufacturers overlook this step. A study by an optical communications consortium suggests that integrating advanced imaging technology can enhance detection rates. Addressing these gaps is crucial for improving overall cable reliability.