-

Home

-

Products

-

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

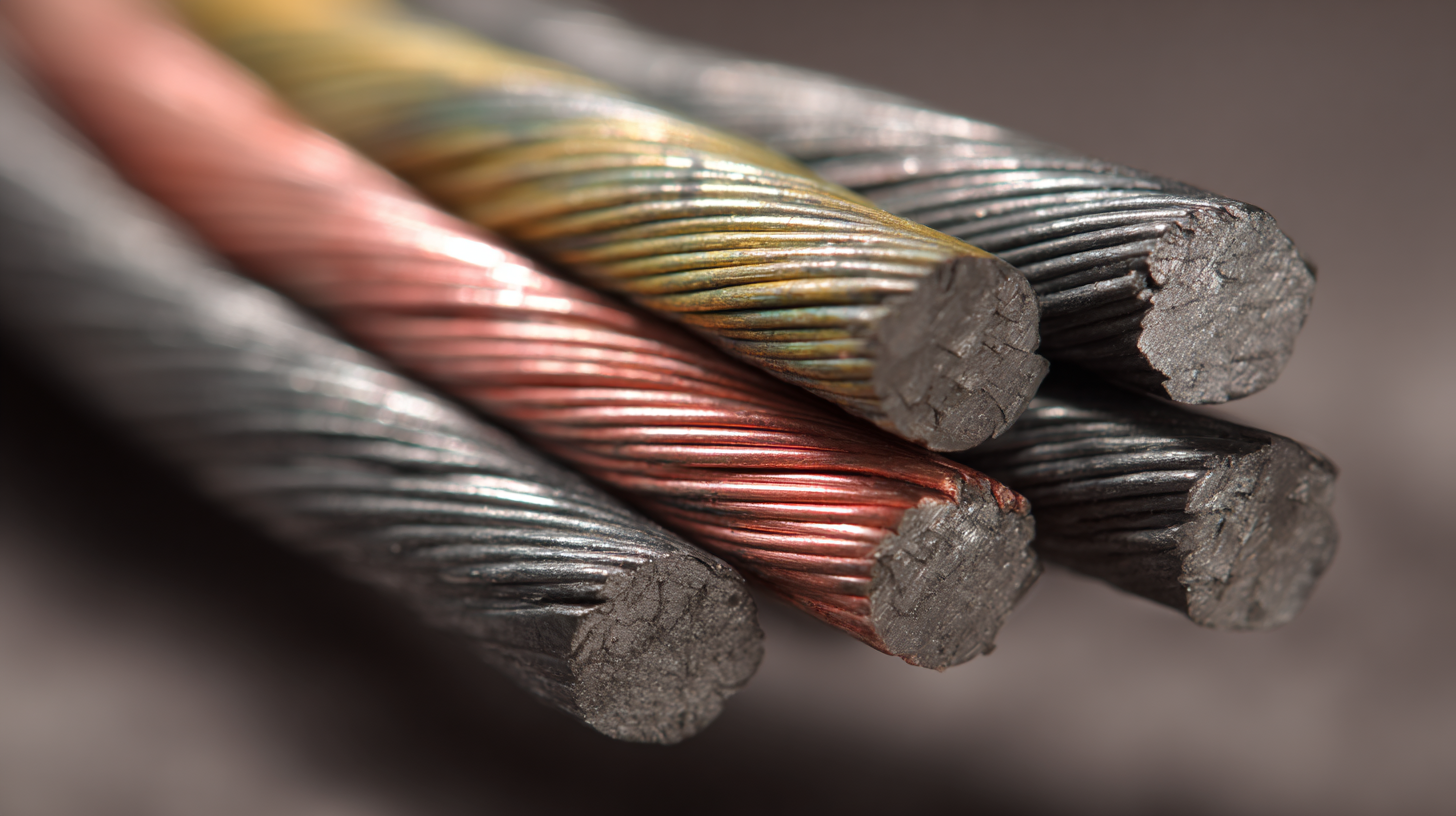

In the field of electrical engineering, the selection of cable material is a critical factor that significantly influences the performance, safety, and longevity of electrical systems. According to a report by MarketsandMarkets, the global market for cable materials is expected to reach $150 billion by 2025, driven by the increasing demand for electricity and the subsequent need for efficient transmission systems. With various materials available, such as copper, aluminum, and fiber optics, each offering distinct advantages and limitations, understanding the implications of cable material selection is essential for engineers. A properly chosen cable can minimize energy losses, ensure compliance with safety standards, and enhance overall system reliability. Consequently, the importance of cable material in electrical engineering cannot be overstated, as it plays a vital role in shaping the future of electrical infrastructure and ensuring sustainable energy practices.

The choice of cable material plays a crucial role in ensuring both electrical safety and performance in various engineering applications. Different materials have distinct properties that affect their conductivity, resistance to heat, and overall durability under varying environmental conditions. For example, copper, known for its excellent conductivity, is often preferred for power transmission cables. However, it is also essential to consider factors like thermal expansion and corrosion resistance, especially in harsh conditions. The wrong material can lead to overheating, signal loss, or even catastrophic failures.

In addition to conductivity, the insulation material surrounding the conductor equally impacts safety. Insulating materials must possess high dielectric strength to prevent failures due to electrical breakdown. Materials such as PVC, XLPE, and rubber are selected based on their ability to withstand not just electrical stresses, but also moisture, chemicals, and mechanical wear. Therefore, the careful selection of both the conductor and insulation materials ensures that cables operate efficiently while minimizing risks, enhancing the overall reliability of electrical systems.

When it comes to electrical engineering, the selection of cable materials is crucial for ensuring performance and safety. Different types of cable materials offer distinct properties that make them suitable for specific applications. For example, copper cables are renowned for their excellent conductivity and flexibility, making them ideal for power transmission where efficiency is a priority. In contrast, aluminum cables are lighter and more cost-effective, which is beneficial for overhead power lines and large-scale installations.

Another significant category is fiber optic cables, which utilize glass or plastic fibers to transmit data signals over long distances with minimal loss. Their immunity to electromagnetic interference makes them perfect for telecommunications and data centers. Additionally, thermoplastic and thermoset materials are often used in insulation for cables, providing protection against environmental factors such as moisture and heat. Understanding the unique advantages and limitations of each cable material is essential for engineers to optimize system design and reliability in electrical applications.

This chart illustrates the electrical conductivity of different cable materials commonly used in electrical engineering. Copper is the most conductive, followed by aluminum, while fiber optic and plastic materials have significantly lower conductivity, showcasing the importance of selecting the appropriate material for specific applications.

Selecting the right cable materials is crucial in electrical engineering, especially given the increasing demand for

renewable energy solutions. The rise of sustainable practices necessitates a careful evaluation of cable materials to ensure they meet the specific needs of projects.

Key factors to consider include the environment in which the cables will be used, the electrical and thermal conductivity

required, and the mechanical properties that can withstand various stresses.

When it comes to electrical engineering, the selection of cable materials plays a critical role in determining both conductivity and durability. Copper and aluminum are two of the most commonly used materials, each with distinct advantages. According to the International Copper Association, copper boasts a conductivity of approximately 59.6 S/m, significantly outperforming aluminum, which has a conductivity of about 37.7 S/m. This high conductivity makes copper the preferred choice for applications requiring minimal energy loss, particularly in power transmission networks.

However, durability must also be considered when evaluating cable materials. Aluminum cables, while less conductive, are lighter and corrosion-resistant, making them suitable for overhead power lines and long-distance transmission. A study by the Aluminum Association indicates that aluminum cables can last up to 30 years under certain conditions, while copper's lifespan can exceed 50 years. This resilience, combined with a lower cost and weight, makes aluminum increasingly appealing in certain applications, despite its lower conductivity. This comparative analysis highlights the necessity of balancing conductivity and durability in cable material selection for optimal performance in electrical engineering projects.

The importance of cable material selection in electrical engineering is increasingly intertwined with the growing focus on sustainability. As renewable energy sources like solar, wind, and hydropower gain traction, the demand for eco-friendly cable materials has surged. The global push for sustainability in various sectors, including construction and transportation, signifies a profound shift towards innovation in cable materials. According to industry reports, the market for sustainable plastic waste management alone is projected to grow from USD 35.81 billion in 2024 to USD 44.45 billion by 2030, demonstrating a clear trend towards greener solutions.

One of the notable fabric innovations reshaping industries is the development of bio-based and smart textiles. These materials not only contribute to reducing carbon footprints but also offer enhanced functionality, making them suitable for a wide range of applications, from fashion to electrical insulation. Adopting these advanced materials can significantly impact cable performance and environmental sustainability.

Tips for selecting sustainable cable materials include evaluating their life cycle impacts and considering options that utilize recycled or renewable sources. Additionally, keeping abreast of emerging technologies and innovations can provide insights into new materials that meet both performance and sustainability criteria. As the market evolves, staying informed will be crucial for engineers looking to make responsible choices in cable material selection.

| Material Type | Conductivity (S/m) | Environmental Impact | Recyclability (%) | Common Applications |

|---|---|---|---|---|

| Copper | 5.8 x 10^7 | Medium | 90% | Power wiring, electronics |

| Aluminum | 3.5 x 10^7 | Low | 80% | Transmission lines, overhead power lines |

| Fiber Optic | N/A | Very Low | 100% | Data communication |

| PVC Insulated | N/A | High | 10% | General wiring, appliances |

| XLPE (Cross-Linked Polyethylene) | N/A | Low | 20% | Power cables, industrial applications |