-

Home

-

Products

-

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

The use of Lszh Irradiated Insulating Cable Material is growing rapidly in various industries. This material offers unique advantages that make it suitable for modern applications. Its resistance to fire and low smoke emission are particularly important.

Lszh Irradiated Insulating Cable Material is known for its durability. It withstands harsh environments better than traditional materials. This characteristic ensures a longer lifespan, which can reduce replacement costs. However, some users may overlook the intricacies of its installation.

While many appreciate its benefits, others may find the material challenging to source or implement. Understanding the specifics of Lszh Irradiated Insulating Cable Material is vital. This is not just about the product but also about adapting practices to fully utilize its potential.

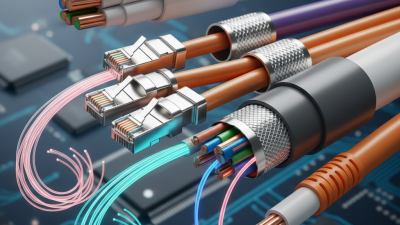

Lszh irradiated insulating cable material is a specialized type of cable insulation. This material is designed for environments with stringent safety and performance requirements. It is made from low-smoke, zero-halogen (LSZH) materials that produce minimal toxic fumes when exposed to fire. This is crucial in confined spaces, such as tunnels and aircraft. The International Electrotechnical Commission (IEC) reports indicate that LSZH materials can reduce smoke generation by up to 60% compared to traditional materials.

The irradiation process enhances the thermal and mechanical properties of the LSZH material. It significantly improves resistance to heat, making it suitable for high-temperature applications. A study by the Institute of Electrical and Electronics Engineers (IEEE) highlights that irradiated insulating materials can withstand temperatures exceeding 90°C. This durability is essential for industries like transportation and construction, where cable failure can lead to significant hazards.

Despite these benefits, the adoption of LSZH irradiated materials is not without challenges. The production process can be complex and costly. Additionally, some installations may not require such advanced materials, leading to potential over-specification. This raises questions about material use efficiency and cost-effectiveness in various applications. Industry professionals must weigh these factors carefully to make informed choices.

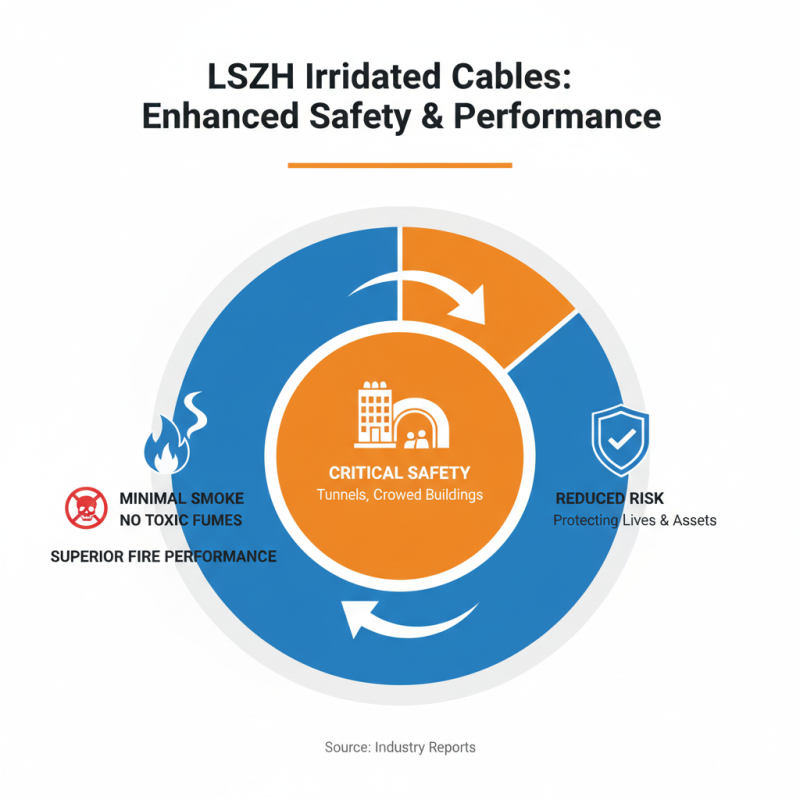

Lszh irradiated insulating cables offer several significant advantages in various applications. One of the main benefits is their enhanced fire performance. According to industry reports, these cables emit minimal smoke and toxic fumes when exposed to flames. In environments where safety is critical, such as tunnels and crowded buildings, this property is invaluable.

Another key advantage is their improved mechanical properties. Irradiation enhances the material’s resistance to abrasion, cut-through, and other forms of wear and tear. This results in a longer service life and reduced maintenance costs. A study by the International Electrotechnical Commission found that LSZH cables, when compared to traditional materials, exhibited a 30% increase in durability.

However, there are challenges associated with these materials. The manufacturing process requires specific expertise and investment. Not every facility can produce high-quality LSZH irradiated cables. This limitation may slow down their adoption in some regions. Additionally, while the initial costs are often higher, the long-term savings from reduced maintenance can offset this. Balancing upfront expenses with future benefits is crucial for decision-makers.

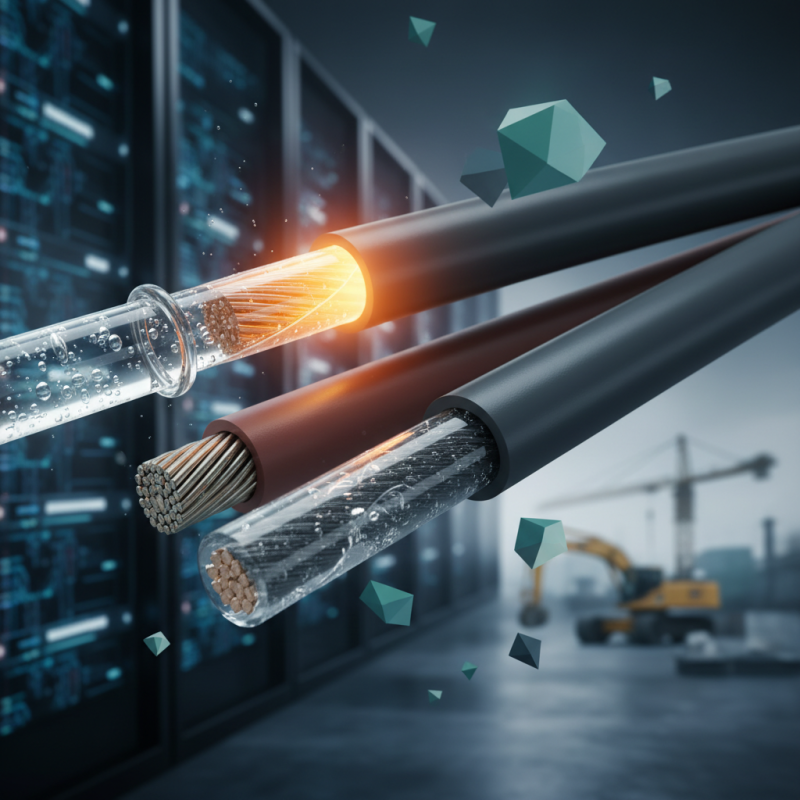

LSZH irradiated insulating cable materials are increasingly used in various applications due to their unique benefits. These cables generate minimal smoke and emit low levels of toxic gases when exposed to fire. This feature makes them ideal for use in public spaces, such as airports and train stations. According to a recent industry report, over 70% of new installations in these areas now favor LSZH materials.

In industrial settings, LSZH irradiated cables are gaining traction. Their ability to withstand high temperatures and harsh environments is crucial. For example, in chemical plants, these cables offer enhanced durability against corrosive substances. A study indicated that the adoption of LSZH materials in such facilities could reduce fire hazards by up to 30%. It's essential for industries to acknowledge the limits of traditional materials compared to LSZH options.

Investment in LSZH technology can yield significant long-term savings. The reduced need for replacements in high-risk environments is one aspect of this. However, transitioning to these materials requires careful evaluation of existing practices. Not every installation will benefit equally. A thorough analysis is needed to avoid unnecessary expenses. The potential is clear, yet implementation must be handled thoughtfully.

When comparing Lszh (Low Smoke Zero Halogen) irradiated insulating cable material to traditional cable insulation, several differences emerge. Traditional materials often emit toxic fumes when burned. In contrast, Lszh materials produce minimal smoke and no halogens, making them safer in emergencies. This is crucial in enclosed spaces like tunnels and public buildings.

Durability is another area of concern. Traditional insulation can degrade under heat or moisture, compromising safety. Lszh irradiated insulation, on the other hand, resists these environmental factors better. It has a longer lifespan and requires less frequent replacement.

However, Lszh may face challenges. Its manufacturing process can be complex, impacting costs. Additionally, some users might hesitate to switch due to familiarity with traditional materials. While the benefits are clear, real-world implementation can pose questions that need addressing.

| Feature | Lszh Irradiated Insulating Cable Material | Traditional Cable Insulation Materials |

|---|---|---|

| Fire Resistance | Excellent | Good, but produces smoke |

| Halogen-Free | Yes | No |

| Environmental Impact | Lower | Higher |

| Durability | High | Medium |

| Thermal Stability | Wide range of temperatures | Limited range |

| Cost | Moderate | Usually lower |

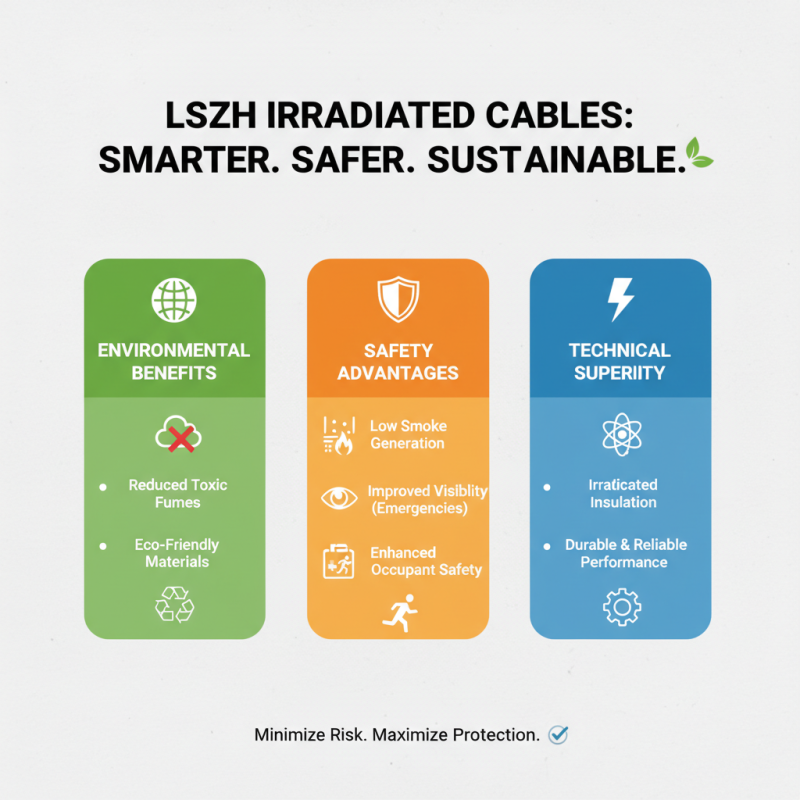

LSZH irradiated insulating cables offer significant environmental and safety benefits. These cables are designed to minimize the release of toxic fumes during fires. Traditional cables often emit harmful substances, posing serious threats to health. In contrast, LSZH cables burn with lower smoke generation, enhancing visibility and safety during emergencies.

Another advantage lies in their eco-friendly composition. The materials used in LSZH cables are less harmful to the environment. They reduce the long-term impact on nature as they do not release hazardous chemicals. Despite their benefits, some challenges exist in their production. The manufacturing process can be more complex and costly. This aspect needs careful consideration for wider implementation.

Choosing LSZH cables can lead to improved safety standards in various applications. Their use is particularly important in densely populated buildings and public areas. However, awareness of their benefits still remains limited. The industry must work harder to educate users about these advantages. Only then can the transition to safer, environmentally friendly solutions occur on a larger scale.