-

Home

-

Products

-

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

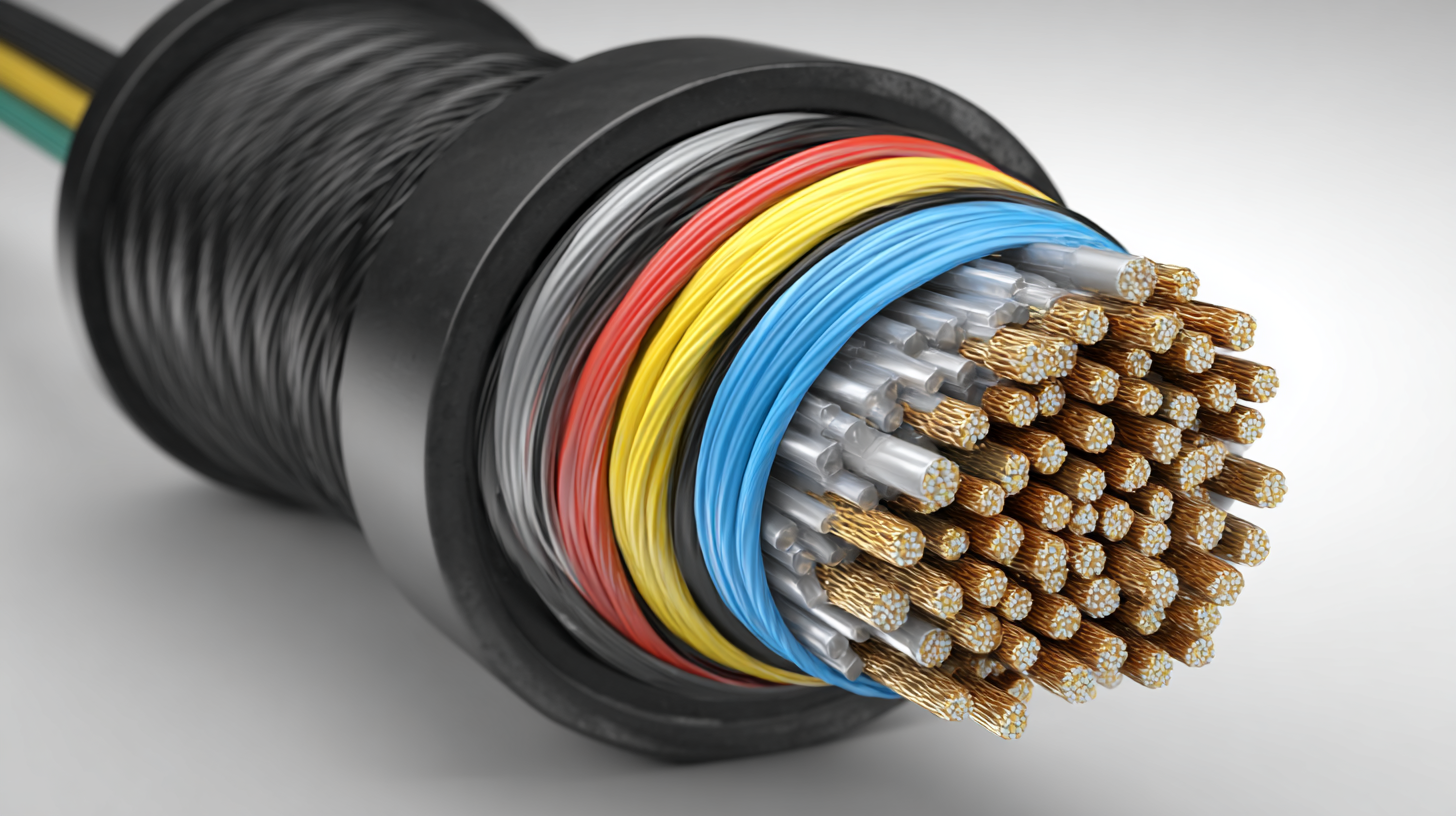

As the demand for efficient and reliable electrical systems continues to rise, the significance of PE cable material in modern electrical applications cannot be overstated. Polyethylene (PE) cable material, known for its excellent insulating properties and resistance to environmental stress, plays a crucial role in ensuring the longevity and performance of electrical installations. According to a report from MarketsandMarkets, the global market for insulated cables, including those made from PE, is projected to reach $237 billion by 2025, growing at a CAGR of 6.3% from 2020. This growth is driven by the increasing adoption of renewable energy sources and advancements in telecommunications infrastructure. As industry standards evolve, understanding the properties and benefits of PE cable material becomes essential for engineers and professionals looking to enhance safety and efficiency in electrical systems.

The importance of polyethylene (PE) cable material in enhancing electrical efficiency cannot be overstated, particularly in the context of the growing focus on renewable energy and sustainable practices. As the demand for efficient energy solutions continues to rise, PE cables have emerged as a critical component in the electrical landscape, offering excellent insulation properties and resistance to environmental factors. These attributes make PE cables ideal for various applications, including solar and wind energy systems, where reliability and performance are key.

Recent advancements in materials science have further amplified the efficacy of PE cables. For instance, the innovation of light-driven and electro-driven polyethylene glycol/two-dimensional MXene form-stable phase change materials demonstrates a significant leap forward in both thermal and electrical conductivity. By integrating such advanced materials, the performance of thermal energy storage systems can be dramatically improved, thereby enhancing the overall efficiency of electrical applications. This synergy between advanced cable materials and renewable energy technologies not only supports market growth but also propels the industry toward a more sustainable future.

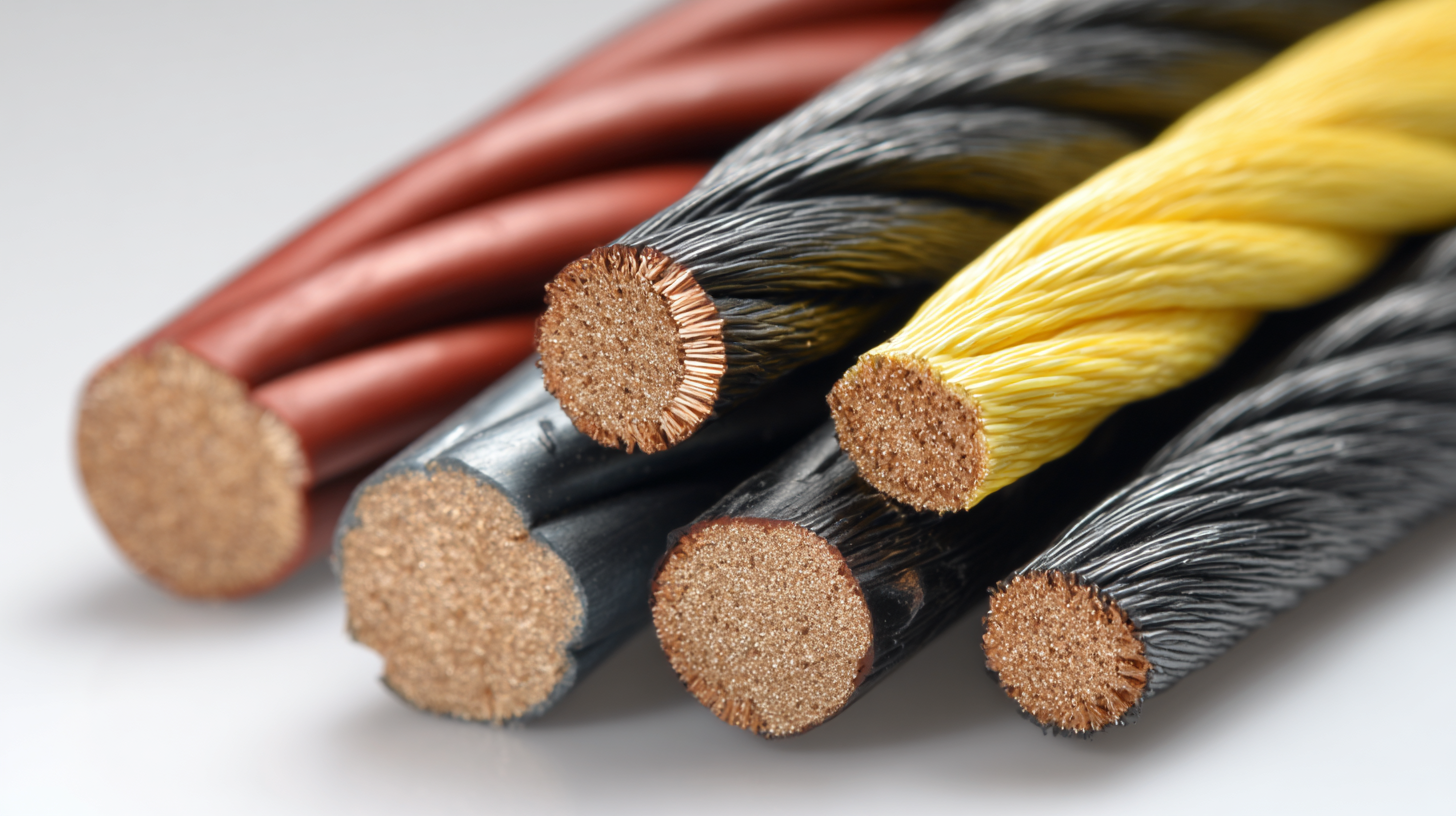

When it comes to electrical applications, the choice of insulation material can greatly affect performance and safety. Polyethylene (PE) cable has emerged as a preferred option compared to traditional insulation materials such as PVC and rubber. One of the key benefits of PE cables is their superior moisture resistance. This characteristic makes them particularly suitable for outdoor installations, where environmental factors can compromise the integrity of the insulation. Unlike PVC, which can become brittle over time, PE maintains its flexibility and strength, ensuring a longer lifespan for electrical installations.

Another significant advantage of PE cables lies in their thermal stability and electrical properties. They exhibit lower dielectric losses, allowing for more efficient transmission of electricity. This contrasts sharply with rubber insulation, which, while flexible, tends to have higher losses due to heat generation. Furthermore, PE cables are lighter and easier to install than traditional options, which can reduce labor costs and improve installation times. This comparative efficiency makes PE a smarter choice for modern electrical projects, addressing both economic and technical requirements effectively.

Polyethylene (PE) cable material has become a staple in modern electrical applications due to its exceptional properties that significantly impact durability. One of the primary advantages of PE is its impressive resistance to moisture and various chemicals, making it particularly suitable for outdoor installations and harsh environments. According to a report by the International Electrotechnical Commission (IEC), PE cables can withstand temperatures ranging from -40°C to +90°C, allowing them to maintain performance even under extreme conditions. This temperature stability ensures minimal degradation over time, extending the lifespan of electrical systems.

Additionally, PE's mechanical strength contributes to its durability. The tensile strength of PE cables can reach up to 25 MPa, a statistic supported by studies from the Electrical and Electronic Engineers (IEEE). This attribute not only prevents physical damage but also ensures reliable performance under stress, significantly reducing maintenance costs and enhancing safety standards. With such characteristics, PE cable material is not just a choice; it's a necessity for ensuring the longevity and efficiency of electrical infrastructure in today's demanding environments.

The rise of renewable energy projects has significantly influenced the demand for PE (Polyethylene) cables, which are increasingly recognized for their durability and resistance to environmental factors. According to industry reports, global PE cable usage in renewable energy initiatives has surged by over 30% in the past five years, particularly in solar and wind applications. As the sector continues to expand, the importance of high-quality cable materials is paramount to ensuring the efficiency and longevity of electrical systems.

Tips: When selecting PE cables for renewable energy projects, ensure that they are designed to withstand extreme temperatures and UV exposure. This not only enhances their performance but also reduces maintenance costs over time.

Moreover, as governments worldwide implement policies promoting sustainable practices, the market for PE cables is expected to grow. In fact, a recent study projects a compound annual growth rate (CAGR) of 8% in the utilization of high-performance cables within the renewable sector. This growth is sparked by both technological advancements in cable production and a societal shift towards greener energy sources.

Tips: Always check for certifications when sourcing PE cables, as this ensures compliance with international standards, enhancing safety and reliability in your projects.

| Application Area | PE Cable Usage (km) | Percentage of Total Usage (%) | Growth Rate (Annual %) |

|---|---|---|---|

| Solar Energy Projects | 15,000 | 40 | 12 |

| Wind Energy Projects | 10,000 | 27 | 10 |

| Hydroelectric Projects | 5,000 | 14 | 8 |

| Geothermal Energy Projects | 3,000 | 8 | 15 |

| Biomass Energy Projects | 2,000 | 5 | 9 |

The future of electrical applications is being significantly transformed by innovations in polyethylene (PE) cable technology, particularly in relation to smart grid solutions. As the demand for more efficient energy transmission and enhanced grid stability grows, the market for cross-linked polyethylene (XLPE) cables is projected to expand substantially. According to recent industry reports, the global XLPE cable market is expected to grow from an estimated $35.84 billion in 2024 to $58.66 billion by 2032, reflecting a compound annual growth rate (CAGR) of 6.35%. This surge underscores the critical role that advanced cable materials play in the development of modern electrical infrastructure.

In parallel, the active cable (AEC) market is also witnessing noteworthy growth. From a valuation of $834 million in 2022, the market is projected to reach $1.212 billion by 2030, demonstrating a CAGR of 5.0% from 2024 to 2030. This indicates a rising interest in innovative cable solutions that can support the dynamic requirements of smart grids, including IoT integration and more responsive energy distribution systems. As these technologies evolve, PE cable materials are poised to become essential components in realizing the full potential of smart infrastructure, ultimately leading to more resilient and efficient electrical systems.

This chart illustrates the importance levels of various factors associated with PE Cable materials in modern electrical applications. As the demand for smart grid solutions increases, understanding these key factors becomes crucial for technological advancements.