-

Home

-

Products

-

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

Photovoltaic Insulation Cable Material plays a crucial role in the renewable energy sector. Industry expert Dr. Emily Zhang emphasizes, "The right insulation can enhance solar panel efficiency significantly." This highlights the material’s importance in ensuring optimal performance in photovoltaic systems.

The characteristics of Photovoltaic Insulation Cable Material are essential for safety and longevity. These materials must withstand extreme temperatures and UV radiation. Additionally, they should possess excellent electrical insulation properties. Such attributes help minimize energy loss and potential hazards. However, not all materials perform equally. There is ongoing debate about which materials yield the best results.

Understanding these key features can be challenging. Some cables may fail under specific conditions, leading to expensive replacements. It is vital to consider not just performance but also long-term reliability. Ensuring the right choice in Photovoltaic Insulation Cable Material is a decision that impacts the sustainability of solar energy solutions.

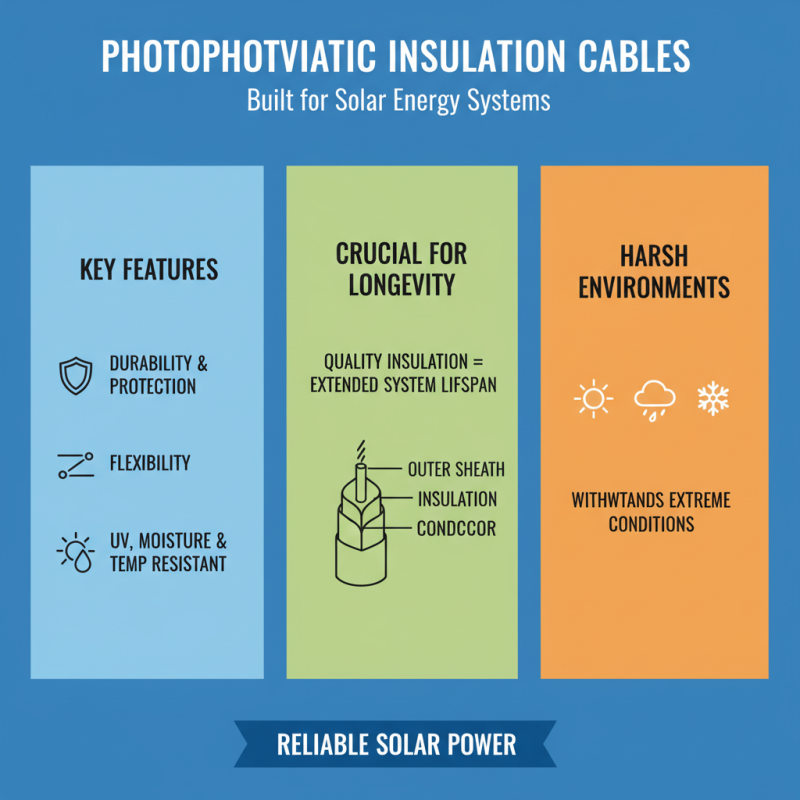

Photovoltaic insulation cables are crucial for solar energy systems. These cables must withstand harsh environments. They offer durability, flexibility, and protection from UV rays, moisture, and temperature changes. The insulation material plays a significant role in ensuring longevity.

One key characteristic is heat resistance. The cables can endure high temperatures without degrading. This feature is essential, especially in sunny climates where solar panels operate. Furthermore, the flexibility of these cables allows for easy installation. Installers can navigate tight spaces without damaging them.

Another element to consider is their electrical performance. High conductivity is vital for minimizing energy loss. This ensures that more energy is harnessed from solar panels. However, not all cables meet these standards. Buyers should look for reliable specifications. Ultimately, choosing the right photovoltaic insulation cable can enhance system efficiency.

Photovoltaic insulation cables play a crucial role in solar energy systems. These cables protect the electrical components from environmental factors and ensure safety and efficiency. The material composition of these cables is vital for their performance and durability in photovoltaic applications.

Typically, photovoltaic cables are made from materials like cross-linked polyethylene (XLPE) and ethylene-propylene rubber (EPR). XLPE offers excellent thermal resistance and electrical insulation. EPR is known for its flexibility and resilience. Reports indicate that cables with XLPE can withstand temperatures from -40°C to 90°C. This is essential for regions with extreme weather conditions.

Tips: Always check the temperature rating of the cable materials used in your installations. Proper insulation prevents overheating and improves longevity.

Additional materials, such as polyvinyl chloride (PVC), are also available. While PVC is cost-effective, it lacks the thermal resilience of XLPE or EPR. These limitations could lead to faster degradation. A survey by a solar energy association found that nearly 30% of power losses stem from inadequate cable protection.

Tips: Regularly inspect cables for signs of wear. Early detection can save money and ensure optimal performance.

Careful consideration of material choices is crucial. Balancing cost, performance, and safety is challenging. Each application may demand different requirements. As the industry evolves, innovations continue to emerge, yet the basics remain significant. Always aim for the highest quality in materials.

Understanding the electrical and thermal performance of photovoltaic insulation cable material is crucial for efficient solar energy systems. The insulation material must withstand various environmental factors. This includes extreme temperatures, moisture, and UV radiation. No one wants to see their solar installation fail prematurely.

Good insulation enhances electrical performance. It prevents current leaks and minimizes energy loss. Cables with high insulation resistance hold an advantage in long-term efficiency. However, it’s not just about resistance. The thickness and quality of the insulation can make a significant difference. Sometimes, manufacturers cut corners to reduce costs. This can lead to overheating and even system failures.

Thermal performance is equally important. Cables often experience heat buildup due to electrical resistance. Choosing the right material helps manage heat dissipation. Silicone and other advanced materials enable better thermal conductivity. However, these materials might be more expensive. Budget constraints can lead to compromised quality. It's a dilemma many face. Balancing performance and cost should always be a priority for optimal results.

When selecting insulation materials for photovoltaic cables, durability and weather resistance are crucial. These cables face extreme conditions, such as harsh sunlight, rain, and fluctuating temperatures. Insulation materials must withstand these elements for longevity. High-quality materials ensure reliable performance over time.

Different materials offer varying levels of resistance. For example, cross-linked polyethylene (XLPE) provides excellent moisture resistance. This quality protects against corrosion and ensures functionality. Alternatively, thermoplastic elastomers (TPE) are flexible and handle temperature variations well, making them a good choice for dynamic environments.

Tips: Always inspect cables for signs of wear. Regular checks can prevent unexpected failures. Choosing materials based on specific environmental conditions can significantly affect performance. Think about the long-term implications of your choices. A lower initial cost might lead to higher maintenance later on.

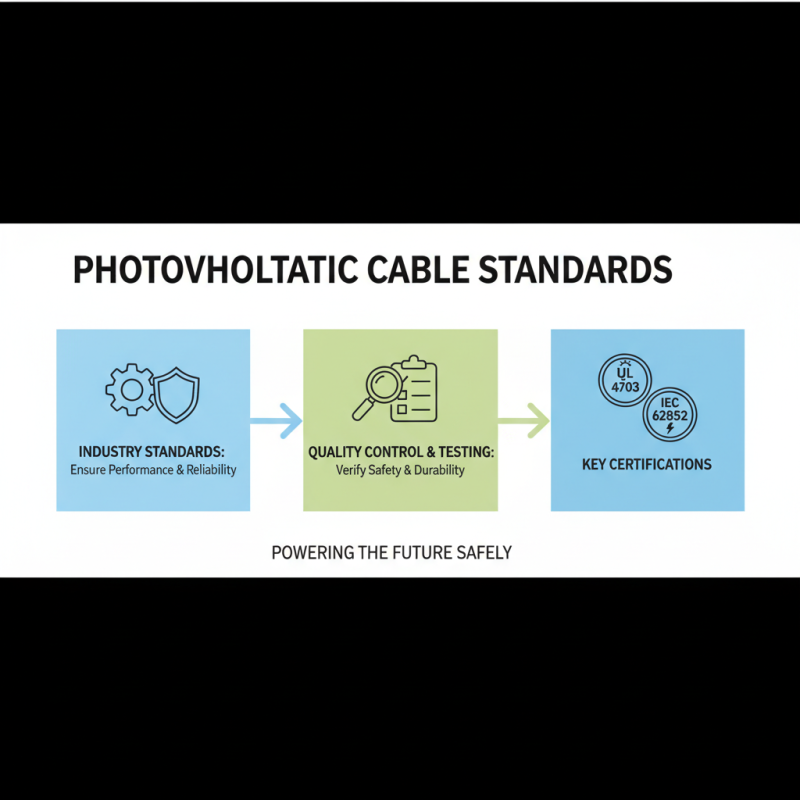

When selecting photovoltaic cables, industry standards play a critical role. These standards ensure that cables perform well in various conditions. Quality control and testing are common practices. They help verify safety and durability. For example, cables must meet UL 4703 or IEC 62852 standards to ensure reliability.

Not all cables are created equal. Some may look good but fail actual performance tests. Choose cables that clearly indicate certifications. This can save time and future costs. Always check for high-temperature ratings and UV resistance. These factors significantly influence cable lifespan.

Tips: Check for environmental certifications. Look for cables that are rated for extreme temperatures. This helps ensure that your system remains efficient in all weather conditions. Remember, the right choice reflects on your installation. Taking the time to research standard compliance pays off in the long run.