-

Home

-

Products

-

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

In the rapidly evolving world of networking, the significance of selecting the right Network Cable Material cannot be overstated. According to a recent report by the International Telecommunication Union (ITU), over 30% of network downtime can be attributed to inadequate cabling infrastructure. This highlights the critical role that high-quality materials play in ensuring optimal performance and reliability. As the demand for faster data transmission and increased network efficiency continues to rise, understanding the various materials available—such as copper, fiber optics, and specialty coatings—becomes essential for network professionals.

Industry expert Dr. Emily Chen, a leading authority on telecommunications infrastructure, emphasizes, “The choice of network cable material directly affects the performance and longevity of the network, making it imperative to invest in high-quality components.” With the right materials, organizations can achieve significant improvements in bandwidth capabilities and reduce the likelihood of signal degradation. In this article, we will explore the top 10 network cable materials that are vital for maximizing performance and ensuring robust connectivity in today’s data-driven environment.

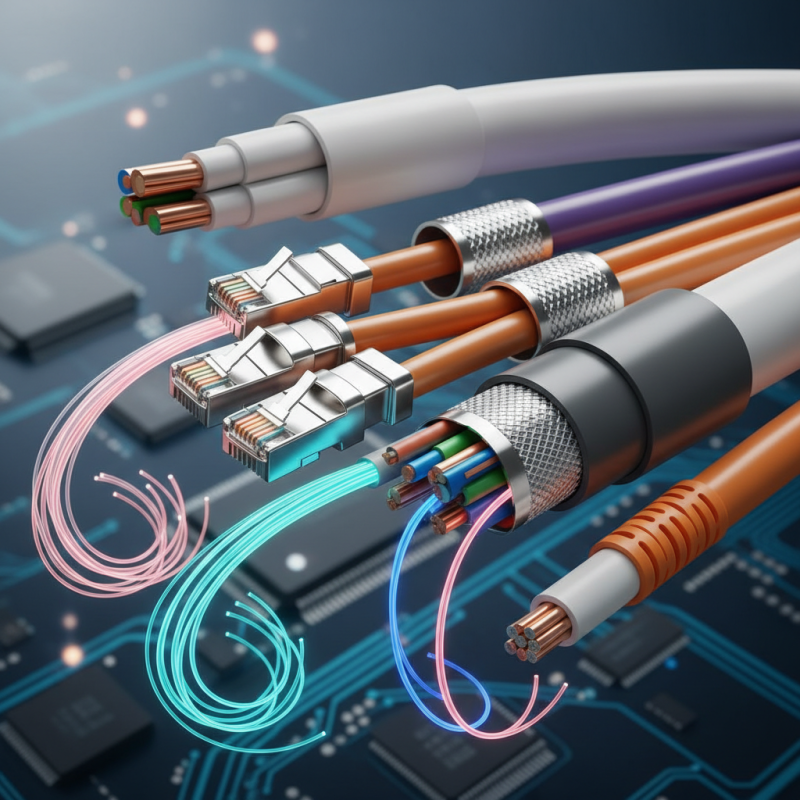

When it comes to achieving optimal performance in network connectivity, understanding the various types of network cables and their materials is crucial. The most common types of network cables include twisted pair cables, coaxial cables, and fiber optic cables.

Twisted pair cables, such as Cat5e and Cat6, are widely used for Ethernet connections, thanks to their balance between cost and performance. They typically consist of copper wire pairs, which help to reduce interference and maintain data integrity. According to a report by the Telecommunications Industry Association, approximately 75% of local area networks (LANs) utilize twisted pair cabling, making it essential to choose the right type for your specific application.

Another important material is the fiber optic cable, which uses glass or plastic fibers to transmit data at the speed of light, significantly outperforming traditional copper cables. Research indicates that fiber optic cables can offer bandwidths exceeding 1Gbps over long distances, making them suitable for high-demand environments like data centers or large enterprises.

Tip: When selecting network cables, ensure that you consider both the distance the signal must travel and the required data speed. Additionally, invest in quality connectors and cables to minimize loss and enhance overall reliability in your network setup. Choosing the right materials can also help mitigate electromagnetic interference (EMI), which is particularly important in environments with heavy electronic equipment.

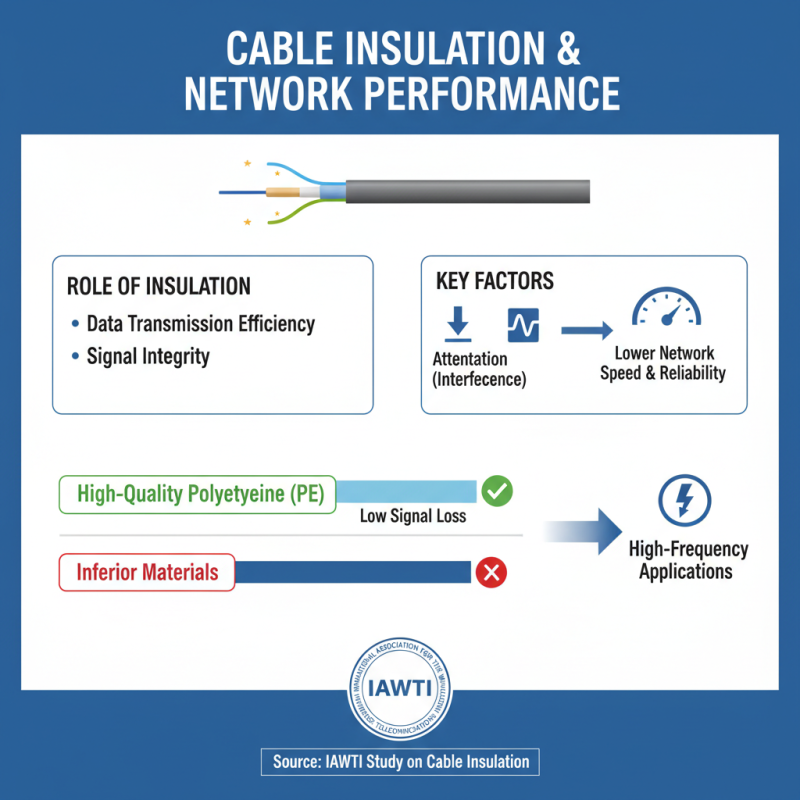

In the world of network performance, cable insulation materials play a crucial role in determining data transmission efficiency and signal integrity. A study by the International Association for the Wireless Telecommunications Industry (IAWTI) highlights that the choice of insulation can affect attenuation and crosstalk, ultimately impacting network speed and reliability. For instance, cables made with high-quality polyethylene (PE) insulation demonstrate lower signal loss compared to those fabricated with inferior materials, making them essential for high-frequency applications.

Moreover, advancements in cable technology have revealed that materials like fluorinated ethylene propylene (FEP) and low-density polyethylene (LDPE) provide enhanced performance in various environmental conditions. According to a report by the Institute of Electrical and Electronics Engineers (IEEE), using such advanced insulation materials can lead to performance boosts of up to 30% in long-distance connections, significantly reducing downtime and improving overall network robustness. This emphasizes the necessity for industry professionals to understand the specific insulating properties of different materials to optimize their network infrastructure effectively.

Fiber optic cables have become the backbone of modern network infrastructure, able to transmit data at unprecedented speeds and significantly outperforming traditional copper cables. As the world increasingly relies on high-speed internet, fiber technology has expanded rapidly, reshaping the telecommunications landscape. In 2023, the fiber optics industry continues to thrive, with service providers implementing strategies to deploy fiber networks faster and at a lower cost, all while improving service quality for users.

When comparing copper and fiber optic cables for networking, the advantages of fiber optics are clear: they offer gigabit-class internet with low latency, making them ideal for both residential and commercial applications. While copper cables are still prevalent, especially in areas lacking infrastructure, fiber optics provide a compelling alternative that can future-proof network capabilities. With the ongoing expansion of fiber networks, millions of people who currently lack access to high-speed connections may soon experience the benefits of this transformative technology.

When it comes to ensuring signal integrity in network cables, the choice of shielding materials is crucial. Shielding not only protects against electromagnetic interference (EMI) but also enhances the overall performance of the network. According to a report by the Institute of Electrical and Electronics Engineers (IEEE), properly shielded cables can reduce crosstalk and external noise by up to 30%, which is vital for maintaining high data transmission rates. The most common shielding types include foil, braided, and a combination of both, each providing different levels of protection and flexibility for various applications. A study conducted by the Telecommunications Industry Association (TIA) highlights that cables with foil shielding are particularly effective in high-frequency environments, such as data centers, where precise signal transmission is paramount. In contrast, braided shielding offers superior durability and mechanical strength, making it ideal for industrial settings. When selecting shielding materials, network designers must consider both the operational environment and the specific performance requirements, ensuring that the chosen material maximizes signal integrity while minimizing latency and loss. Through careful evaluation of shielding options, stakeholders can significantly enhance their network's efficiency and reliability.

When selecting network cables, durability and flexibility are paramount for optimal performance. With the growing demand for high-speed internet and streaming services, the choice of materials becomes even more critical. Copper remains a dominant choice due to its superior conductivity and flexibility, essential for maintaining signal integrity over long distances. Recent market analyses indicate that the global copper wire market size is projected to reach USD 284.70 billion by 2034, underscoring its significance in networking applications.

Tips: When assessing network cable options, consider the environmental conditions in which the cables will be used. For instance, cables with enhanced resistance to abrasion and temperature fluctuations tend to last longer and sustain performance levels. Additionally, look for cables that comply with current industry standards; this ensures not only durability but also optimal flexibility for easy installation in various settings.

Opting for high-quality materials can significantly enhance the lifespan and reliability of your network. Microduct cables, for example, are gaining traction in the market, with a projected CAGR of 11.5%, offering robust solutions suitable for modern infrastructure. Investing in such products can help mitigate issues like signal loss and downtime, ultimately supporting efficient network operations.