-

Home

-

Products

-

PVC Cable Material

-

Low Smoke Zero Halogen Cable Material

-

Cable material

-

Optical fiber cable

-

-

About Us

-

VR

-

News

-

Blog

-

Contact Us

Leave Your Message

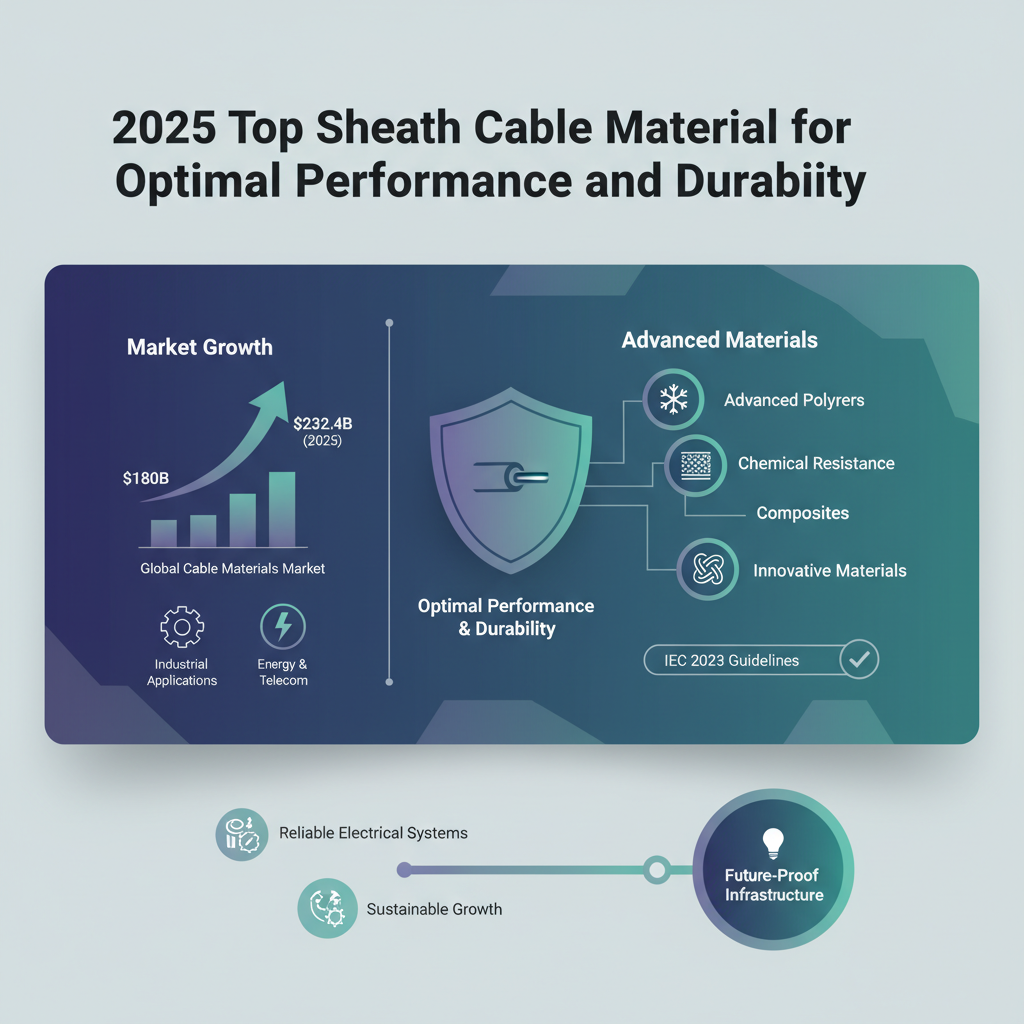

The choice of sheath cable material is a crucial factor in ensuring optimal performance and durability in various industrial applications. According to a recent report by MarketsandMarkets, the global cable materials market is projected to reach $232.4 billion by 2025, highlighting the increasing demand for high-quality materials that can withstand environmental stressors. The right sheath cable material contributes not only to electrical insulation and protection but also plays a significant role in enhancing the longevity of cables in diverse settings, from telecommunications to energy transmission.

In 2023, the International Electrotechnical Commission (IEC) established new guidelines indicating that advanced polymers and composites are becoming increasingly favored for sheath applications, owing to their superior resistance to abrasion, temperature extremes, and chemical exposure. As industries evolve and become more dependent on reliable electrical infrastructures, the development of innovative sheath cable materials is expected to keep pace with these demands. Consequently, understanding the characteristics and advantages of various materials is essential for manufacturers aiming to deliver products that comply with international standards while offering the resilience needed for future growth.

When considering the optimal performance and durability of sheath cable materials in 2025, several key characteristics stand out. According to a recent report from the International Electrotechnical Commission (IEC), flexible and robust insulation materials are crucial for high-frequency applications, with polyvinyl chloride (PVC) and cross-linked polyethylene (XLPE) leading the charge. These materials not only demonstrate superior electrical insulation properties but also exhibit high resistance to environmental factors such as moisture and UV radiation, enhancing their longevity in diverse applications.

Another important characteristic is thermal stability, which has been emphasized by the Institute of Electrical and Electronics Engineers (IEEE). For instance, the adoption of thermoplastic elastomers (TPE) is on the rise, as they provide excellent heat resistance and mechanical flexibility. Data from Frost & Sullivan indicates that the market for TPE in cable sheathing is projected to grow by 15% annually through 2025. This growth is largely driven by their applications in electric vehicles and renewable energy sectors, where the demand for durable, high-performance materials is at an all-time high. As technology evolves, the focus on these characteristics will be essential to meet the increasing demands for reliable and efficient sheath cable materials.

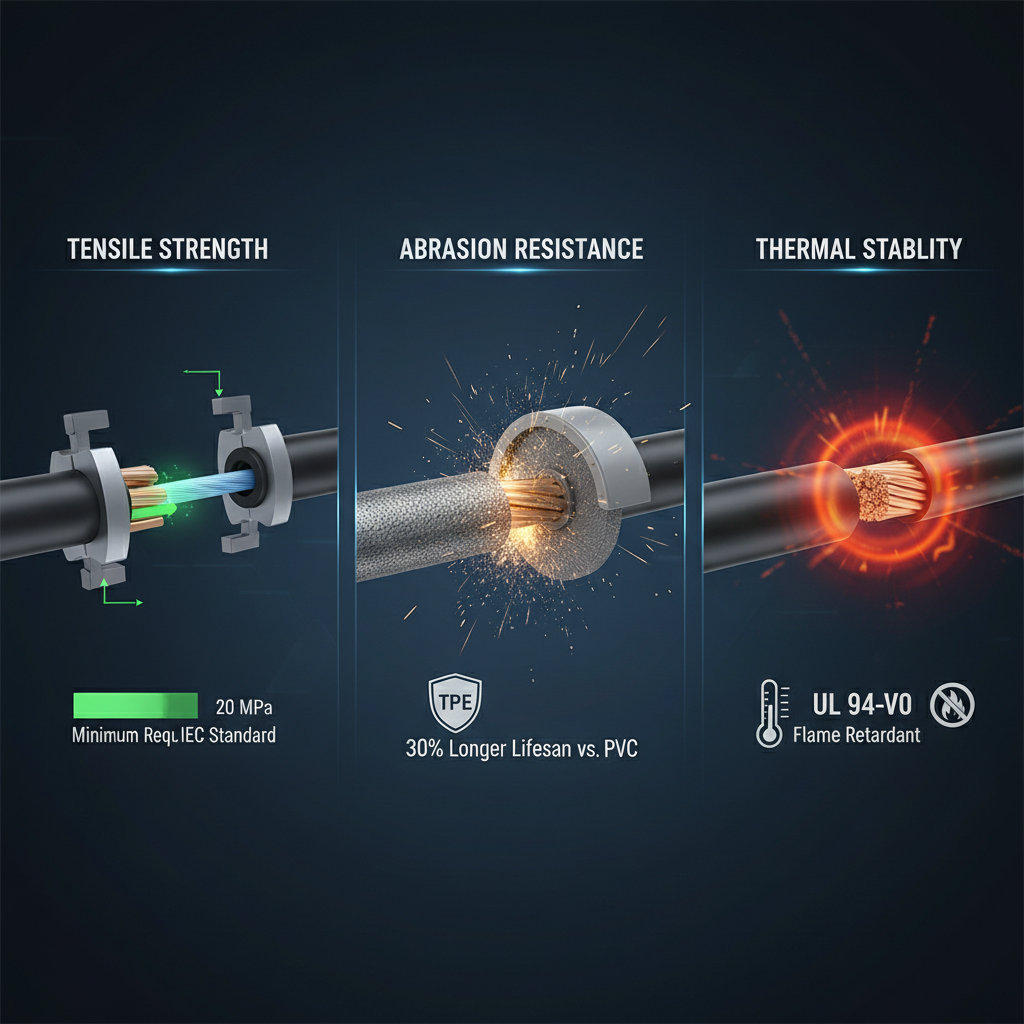

The performance of sheath cables largely depends on key metrics such as tensile strength, abrasion resistance, and thermal stability. According to the International Electrotechnical Commission (IEC), cables should maintain a tensile strength of at least 20 MPa to ensure reliability during installation and use. Additionally, materials with high abrasion resistance can significantly extend the lifespan of the cable, reducing maintenance costs over time. The use of thermoplastic elastomers (TPEs) has been shown to improve durability in harsh environments, with studies indicating an up to 30% increase in lifespan compared to traditional PVC sheathing.

Tips: When selecting sheath cable materials, consider the environmental conditions they will be exposed to. For applications in high-temperature areas, prioritize materials with superior thermal stability, and consult technical data sheets for detailed performance metrics. Furthermore, always verify compliance with industry standards like UL and IEC to ensure optimal functionality and safety.

Another crucial aspect is the cable's flexibility, which is vital for applications requiring frequent movement. A report from Cables & Connectivity Industry Association reveals that cables with a smaller bend radius maintain consistent performance, avoiding signal loss and mechanical stress. Evaluating these key performance metrics not only enhances the efficiency of your network but also guarantees long-term durability and value.

When selecting sheath cables, durability is a critical factor that can significantly impact performance. Industry studies indicate that cables made from high-quality materials, such as polyvinyl chloride (PVC) and thermoplastic elastomer (TPE), offer superior resistance to wear and tear, prolonging their lifespan. In fact, cables constructed with these materials can withstand more than 15,000 cycles of bending, as highlighted in reports from leading industry analysts. This resilience not only prevents fraying but also ensures that the cables deliver consistent power and data transmission.

Additionally, factors such as tensile strength and temperature ratings also play a decisive role in the overall durability of sheath cables. Research shows that cables engineered to endure extreme temperature fluctuations and mechanical stress can maintain optimal performance even in challenging environments. For instance, cables rated for temperatures between -40°C to 85°C are becoming increasingly common in both consumer and industrial applications. As the demand for reliable and durable charging solutions continues to rise, focusing on these durability factors will be crucial for selecting the best sheath cables in 2025.

The evolution of sheath cables is largely influenced by innovative materials that enhance performance and durability. One of the most promising advancements is the development of polymer blends that combine flexibility with strength. These materials not only withstand extreme temperatures but also resist abrasions and chemical exposure, making them ideal for various applications in both indoor and outdoor settings. Manufacturers are increasingly turning to thermoplastic elastomers (TPEs) which offer superior mechanical properties while being lightweight and environmentally friendly.

In addition to TPEs, advancements in nanotechnology have led to the creation of composites that integrate conductive nanoparticles. This technology enhances electrical performance and thermal conductivity, which is crucial for high-capacity applications. Moreover, the use of self-healing materials provides an extra layer of durability, ensuring that minor damages can be automatically repaired, thus extending the lifespan of sheath cables. As these innovative materials continue to shape the future, they promise not only to improve the efficiency of electrical systems but also to contribute to a more sustainable future in cable manufacturing.

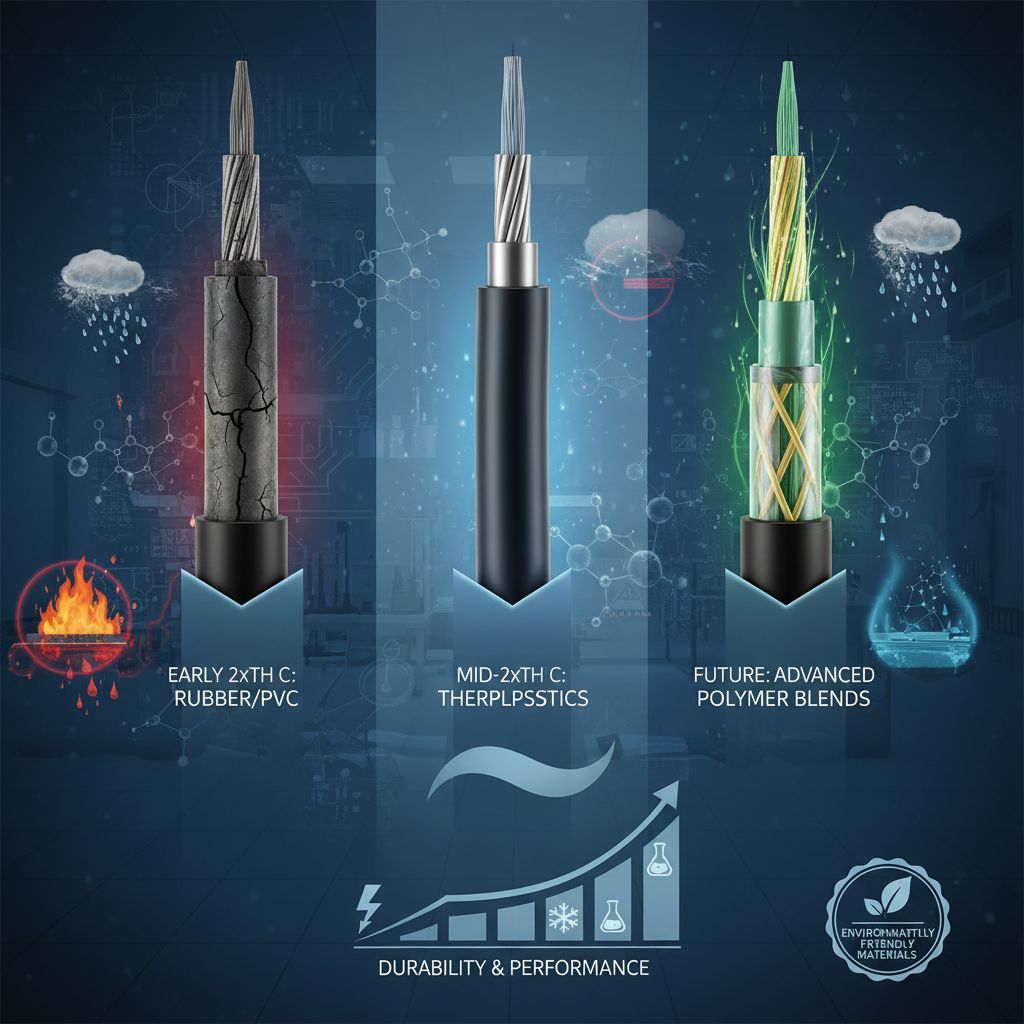

The choice between traditional and modern sheath cable materials significantly impacts performance and durability in various applications. Traditional materials, such as PVC and rubber, have long been favored for their flexibility and resistance to environmental factors. However, they may fall short in extreme conditions, leading to degradation over time. While they provide a cost-effective solution, the reliance on these older materials can increase maintenance costs and reduce lifespan, particularly in demanding environments.

In contrast, modern materials like thermoplastic elastomers (TPE) and cross-linked polyethylene (XLPE) are emerging as superior alternatives. These materials exhibit enhanced resistance to abrasion, UV exposure, and chemicals, offering greater durability and longevity. Additionally, they often boast improved thermal stability and a lower environmental impact due to their recyclability. As industries evolve and demand higher performance standards, the transition towards modern sheath materials is not only a strategic choice but also a necessary one to meet the challenges of contemporary applications.